Best Swinging Door Solutions

Searching for the best swinging door solutions for food processing facilities? This guide breaks down why food plants need specialized doors, highlights the top four models, explains what to look for when choosing, offers maintenance tips, and answers key questions to help you pick the right door for your operation.

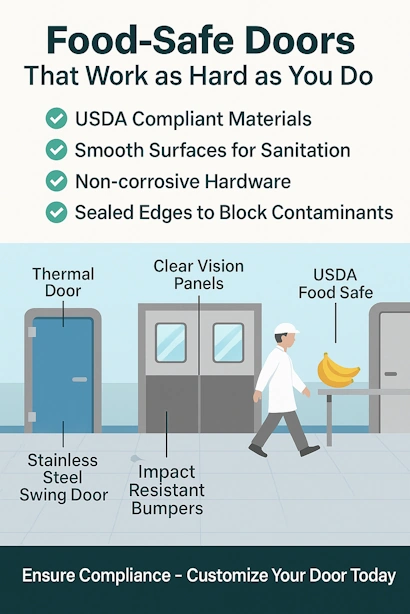

Ensure USDA Compliance

Food processing facilities must have swinging doors that meet tight criteria. This infographic shows you exactly what to look for. Every aspect is important for keeping things clean and safe, from materials that meet USDA standards to smooth, easy-to-clean surfaces and bumpers that can withstand impact. Choosing the right door is important whether you're updating just one area or the whole building. Do you have questions or need a solution made just for you? Get in touch with us immediately for experienced help and pricing.

Why Food Processing Facilities Can’t Use Just Any Door

The right door does more than open and close; it protects the entire workflow of your facility. In food processing environments, where hygiene and efficiency are everything, choosing the wrong type of door can lead to costly consequences. Below, we break down the core challenges facilities face and how the right swinging door helps solve them.

What Happens When the Wrong Door Is Installed

Standard doors aren’t built for the demands of a food processing plant. They struggle with constant cart traffic, allow cold air to escape, and can harbor bacteria in hard-to-clean surfaces.

Over time, this leads to energy waste, frequent breakdowns, and even failed health inspections. These everyday setbacks may seem minor at first but can quickly snowball into serious issues that disrupt operations and put compliance at risk.

What the Right Swinging Door Does Differently

A well-designed swinging door helps maintain cold room temperatures, resists heavy impacts, and supports frequent sanitation. Its smooth and its surface is non-porous which makes it easy to clean, while sealed edges prevent contamination from spreading between work zones.

On top of that, it’s built to last under 24/7 use, helping you meet USDA and FDA standards while reducing the need for costly repairs or replacements.

The Top 4 Swinging Door Solutions for Food Processing

Once you understand the risks of using the wrong door, the next step is matching the right one to your environment. Below are four of the most trusted swinging door models used in food processing. Each one is tailored for specific areas, traffic types, and sanitation needs.

This is a go-to option for light-use areas where functionality and ease of cleaning matter most. Commonly used in prep spaces, dry storage, or hallways with light cart traffic, the PE-1500 offers flexible performance without overengineering.

- Lightweight polyethylene panel allows easy swing-through

- Smooth surface cleans quickly with basic sanitation procedures

- Optional acrylic windows improve visibility between rooms

- Great for entry points between work zones with low impact

- Cost-effective option for areas without extreme wear

For rooms where hygiene is non-negotiable, like cleanrooms, meat-cutting zones, or high-sanitation corridors, the PE-9000 delivers full compliance and easy sanitation.

- Seamless, non-porous panel helps prevent bacteria buildup

- Designed for high-pressure washdown and daily sanitation cycles

- Stainless steel hinge hardware resists rust and corrosion

- Full-perimeter seal supports environmental separation

- Meets USDA and FDA standards for food contact environments

Maintaining consistent cold temperatures is critical in food production. The PE-8000 is built to help control airflow and moisture in freezer spaces, refrigerated zones, and cold prep areas.

- Insulated foam core reduces thermal loss and energy waste

- PVC outer skin resists condensation and mold

- Perimeter gaskets block temperature exchange at the frame

- Compatible with heavy-duty hinges for frequent open/close cycles

- Reliable option for food safety in chilled environments

4. PEX-9000 – Heavy-Duty Impact Door

Heavy traffic requires heavy-duty solutions. The PEX-9000 is built for logistics zones, loading docks, and production lines with forklifts or pallet jacks in constant use.

- Reinforced polyethylene stands up to repeated impacts

- Optional bumpers and kickplates extend door life

- Non-porous surface cleans easily despite industrial wear

- Withstands aggressive traffic without warping or cracking

- Perfect for zones where efficiency and durability are top priorities

What to Look For When Choosing a Food-Grade Swinging Door

After identifying which door type suits each area of your facility, the next step is knowing what specific features to look for. Whether you're managing a high-traffic cold storage room or a USDA-regulated prep area, choosing the right components ensures compliance, durability, and worker safety.

Here are the most important factors to consider when selecting a food-grade swinging door:

| Feature | Why It Matters |

|---|---|

| ✅ Hygienic, Crevice-Free Surfaces | Smooth, non-porous materials like ABS or HDPE are easy to sanitize and resist bacteria, moisture, and chemical buildup—essential for sanitary food environments. |

| ✅ Insulated Cores for Temperature Control | Perfect for cold storage or freezers, insulated cores help maintain internal temperatures, reduce energy waste, and meet cold chain safety standards. |

| ✅ High-Cycle Hinges for 24/7 Operation | Facilities with constant traffic benefit from hinges built for durability, supporting frequent open/close cycles without frequent maintenance. |

| ✅ Full-Perimeter Gaskets for Air and Seal Control | Gaskets help maintain controlled environments by preventing air exchange, condensation, and contaminants—ideal for cleanrooms and cold zones. |

| ✅ Optional Windows for Safety and Visibility | Vision panels allow safe line-of-sight in high-traffic corridors, reducing collisions and accidents between staff and carts. |

| ✅ Frame Compatibility for Easy Installation | Many food-grade doors can be installed with retrofit kits or 3-piece stainless frames, making them easy to fit into existing wall setups. |

By keeping these features in mind, you'll be better equipped to choose a door that aligns with your operational flow, compliance requirements, and safety standards.

Installation & Maintenance Tips for Long-Term Performance

Installing your door is only the beginning; keeping it performing at its best takes just a few smart habits.

Once you've chosen the right food-grade swinging door for your facility, proper setup and maintenance will ensure it works reliably for years. The good news? It’s easier than you think. Follow these simple, step-by-step tips to make installation smooth and extend the life of your investment.

| Step | Tip |

|---|---|

| 🛠 Step 1: Install with the Right Fit | Most quality doors are designed to work with standard wall openings. If you're retrofitting or using 3-piece stainless steel frames, choose a model that includes compatible hardware kits. This makes the installation process quick, clean, and disruption-free. Pro Insight: Always measure frame clearances and verify compatibility before ordering to avoid unexpected retrofitting delays. |

| 🔍 Step 2: Set a Monthly Maintenance Routine |

A regular check-up keeps your door performing like new. Here's what to include: ✅ Inspect hinges for looseness, sagging, or misalignment ✅ Clean both sides with food-safe disinfectants to prevent buildup ✅ Examine gaskets for tears or worn compression that can impact the seal |

| 🧠 Step 3: Add Doors to Your HACCP Checklist |

Don’t wait for issues to escalate. Including swinging doors in your facility’s HACCP (Hazard Analysis Critical Control Point) plan helps you catch problems early: • Look for signs of physical wear • Monitor seals for air leakage or condensation • Schedule minor fixes before they become costly repairs |

| ✅ Step 4: Extend the Life of Your Investment |

By following a consistent maintenance schedule and choosing the right model from the start, you’ll: • Preserve temperature control • Improve workplace hygiene • Avoid breakdowns that stall operations |

With the right door model and a proactive care routine, your facility won’t just stay compliant, it’ll stay efficient.

A bit of routine care today can help you sidestep bigger problems tomorrow. Whether you're managing cold storage, clean zones, or high-traffic prep areas, these tips will help your door support hygiene, safety, and performance every single day.

Frequently Asked Questions

FAQs: Swinging Doors for Food Facilities

What’s the most hygienic swinging door option for food plants?

The PE-9000 Hygienic Door is our most sanitation-friendly model. It’s built with a smooth, crevice-free HDPE panel that resists bacterial growth and daily washdowns. This model is perfect for USDA and FDA-regulated zones like meat-cutting rooms and cleanrooms.

Are your swinging doors USDA and FDA compliant?

Yes, our PE-9000 model is fully compliant with USDA and FDA food safety standards. With stainless steel hardware, a full-perimeter seal, and non-porous surfaces, it’s built to pass inspection and maintain hygiene in processing environments.

Can swinging doors be used in cold storage or freezer areas?

Absolutely. The PE-8000 Cold Storage Door includes an insulated core and PVC outer skin to control thermal loss and prevent condensation. It’s ideal for freezers, refrigerated prep zones, and other cold-chain spaces.

Do you offer swinging doors for high-impact or forklift-heavy zones?

Yes. Our PEX-9000 Heavy-Duty Impact Door is designed for rugged use in areas like loading docks and pallet staging zones. It features a reinforced polyethylene panel and optional bumpers to handle frequent forklift traffic.

Can these doors be retrofitted into existing frames?

Yes. Many models, including the PE-1500 and PE-8000, are available with retrofit kits or 3-piece stainless frames. These ensure fast and clean upgrades without major structural changes.

How long do these food-grade swinging doors typically last?

With proper care, our swinging doors last 10 to 15 years in high-use environments. Durable core materials, high-cycle hinges, and sealed edges support long-term performance without frequent replacements.

Do your swinging doors support HACCP compliance?

Yes. Models like the PE-9000 and PE-8000 support HACCP programs by helping control contamination risks. Their easy-clean surfaces, visibility options, and reliable seals make them a smart fit for food safety planning.

Are vision panels or windows available?

Definitely. Optional vision panels can be added to most models, including the PE-1500 and PE-9000, to improve safety and line-of-sight in busy or two-way traffic areas.

What swinging door is best for general-purpose food facility use?

The PE-1500 All-Purpose Door is ideal for light-duty areas such as prep rooms, dry storage, or hallways. It’s budget-friendly and easy to clean while still meeting sanitation needs.

Do you offer custom sizes or configurations?

Yes. All of our swinging doors are available in custom sizes and configurations. We also offer add-ons like windows, kick plates, and frame kits to match your facility layout.

Photo Gallery

Conclusion: The Right Door = A Safer, Smoother Facility

In food processing environments, even small equipment decisions can have a big impact. Choosing the right swinging door isn’t just about what fits, it's about what protects. From maintaining strict hygiene standards to streamlining daily operations, the right food-grade door helps you safeguard your product, your team, and your bottom line.

Whether you're retrofitting a USDA-inspected prep room or building out a new cold storage zone, investing in the right door now means fewer disruptions, fewer safety concerns, and fewer compliance headaches later. Ready to take the next step? Explore Traffic Swinging Doors' full line of food-grade solutions or request a custom quote tailored to your facility’s needs.