Industrial Impact Doors

Industrial facilities face constant wear from forklifts, carts, and nonstop traffic, leading to damaged doors and costly downtime. This guide explains how Industrial Impact Doors solve these challenges and helps you choose the right model for your facility. You’ll learn how they enhance durability, safety, and efficiency in high-traffic environments.

Designed for Industrial Durability & Safety Standards

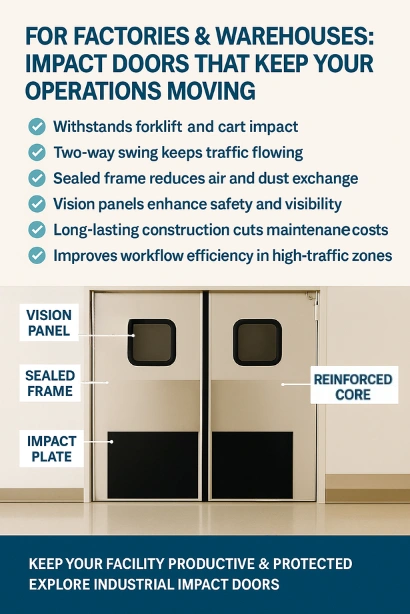

Industrial Impact Doors are designed for the toughest environments, handling forklifts, carts, and nonstop traffic with ease. Whether you’re managing a warehouse, factory, or cold storage facility, the right door keeps your operation efficient and safe. Explore our PE-Series Industrial Impact Doors today to see how durable design, reinforced cores, and sealed construction can help protect your workflow and reduce costly downtime across every part of your facility.

What Is an Industrial Impact Door and Why It Matters

Now that you understand why choosing the right door matters, let’s look at what makes Industrial Impact Doors different. These doors are built for strength and performance, designed to keep up with the constant demands of busy industrial environments where reliability is essential.

Built for Heavy-Duty Performance and Smooth Operations

Built for Nonstop Industrial Use

Unlike standard swinging doors, Industrial Impact Doors are designed for heavy-duty areas where movement never stops.

They handle continuous pressure from carts, forklifts, and staff without bending or warping, maintaining their alignment even after thousands of daily uses. This makes them a dependable choice for facilities that operate around the clock.

Designed to Keep Workflow Smooth and Safe

These doors feature reinforced panels, heavy-duty hinges, and a two-way swing that allows traffic from both directions without delays.

The design prevents slowdowns in busy corridors and helps staff move safely and efficiently through high-traffic zones, making daily operations more seamless and predictable.

Made for Strength, Reliability, and Everyday Efficiency

Built for Performance and Protection

Every component of an Industrial Impact Door serves a purpose. The reinforced core and sealed frame prevent dents, cracks, and air leaks that can disrupt climate control or productivity.

This sturdy build protects equipment, inventory, and employees while keeping doors operating at peak performance for years.

Designed for Demanding Industrial Environments

The combination of durable materials and precision engineering helps minimize downtime and repair costs. These doors are ideal for warehouses, logistics hubs, cold-storage areas, and manufacturing plants that rely on smooth operations and long-term reliability.

Their dependable design ensures consistent performance under constant movement and impact.

Featured Industrial Impact Door Models for Every Operation

Not every facility faces the same challenges, which is why we offer a selection of Industrial Impact Doors designed for different workflows. Each model serves a specific purpose, helping you maintain safety, efficiency, and consistency across high-traffic environments.

The PC-1500 is engineered for the most demanding work areas where forklifts and heavy carts move continuously. Its durable structure keeps up with high-impact conditions and helps minimize maintenance interruptions.

• Built to withstand constant impact in high-traffic industrial settings

• Smooth, self-closing swing supports nonstop equipment flow

• Reduces downtime in warehouse and production areas

• Ideal for heavy-load and distribution environments

PE-8000 – Lightweight Design, Heavy-Duty Performance

The PE-8000 delivers effortless movement and lasting reliability for fast-paced work zones. It’s the right choice for facilities where lightweight operation and durable performance are equally important.

• Easy-swing design enhances worker speed and efficiency

• Maintains strength under repeated, high-frequency use

• Helps prevent workflow delays in production and assembly areas

• Ideal for manufacturing, food prep, and packaging lines

The PE-9000 is built for temperature-sensitive and high-moisture areas that demand both durability and insulation. Its dependable construction ensures protection against environmental wear while maintaining stable conditions.

• Excellent insulation for cold storage and controlled environments

• Helps reduce air transfer and maintain consistent temperatures

• Resists wear from daily traffic and frequent equipment movement

• Perfect for food processing, storage, or pharmaceutical facilities

The PEX-9000 combines durability and flexibility for general-purpose industrial spaces. It’s ideal for areas that experience steady foot or cart traffic and need reliable protection without the weight of heavier models.

• Designed for medium-impact areas with frequent daily use

• Durable core provides long-lasting performance with minimal upkeep

• Supports smooth two-way traffic in smaller operational zones

• Ideal for maintenance areas, retail stockrooms, and light industrial settings

Industrial Impact Door vs. Standard Door

After exploring each model’s unique strengths, it’s clear that not all industrial doors perform the same. The difference between a standard industrial door and an Industrial Impact Door comes down to durability, efficiency, and long-term reliability. The comparison below shows how upgrading makes a measurable impact in any high-traffic facility.

| Feature | Industrial Impact Door | Standard Industrial Door |

|---|---|---|

| Durability | Reinforced panels and heavy-duty hardware absorb frequent impact without bending or cracking. | Prone to dents, misalignment, and surface wear under daily use. |

| Traffic Flow | Dual-swing motion supports forklifts, carts, and workers moving in both directions. | Single swing causes traffic delays and limited access. |

| Maintenance | Long-lasting materials require minimal repairs, even in busy environments. | Frequent repairs and replacements increase downtime. |

| Safety | Clear vision panels and consistent swing action reduce collision risks. | Limited visibility and rigid design create potential safety issues. |

| Energy Efficiency | Insulated cores and tight seals help maintain temperature control. | Air gaps and poor sealing lead to energy loss. |

| Lifespan | Engineered to last up to five times longer in heavy-duty conditions. | Shorter lifespan when exposed to repeated impact. |

| Best For | Warehouses, manufacturing plants, logistics centers, and cold-storage facilities. | Light commercial areas or low-traffic spaces. |

When you compare the two, the choice becomes clear. Industrial Impact Doors offer the reliability, safety, and performance that busy facilities demand every day. Investing in the right door doesn’t just protect your operation, it helps your team move faster, stay safer, and keep productivity high for years to come.

How to Choose the Right Industrial Impact Door for Your Facility

After seeing how Industrial Impact Doors stand apart from standard ones, the next step is finding the right fit for your facility. Every space has its own traffic demands and environmental conditions, here’s how to identify which door best meets your daily needs.

| Step | How It Helps You Choose the Right Door |

|---|---|

| ✅ Identify Your Facility’s Traffic Type | Observe whether your facility handles forklifts, carts, or foot traffic. High-impact areas need reinforced models like the PC-1500, while light-duty spaces benefit from doors that open easily and close quietly. |

| ✅ Measure Door Openings and Clearance Needs | Take accurate height, width, and clearance measurements to ensure a proper fit. Correct sizing prevents misalignment and reduces wear from repeated traffic. |

| ✅ Consider Environmental Factors | Match your door to its surroundings. For temperature-sensitive or humid spaces, insulated models like the PE-9000 work best. For general areas, the PE-8000 or PEX-9000 maintain durability and easy movement. |

| ✅ Match Material and Swing Style to Frequency of Use | Constant-use areas require impact-resistant cores and heavy-duty swing systems. For moderate traffic, lighter materials reduce strain while maintaining energy efficiency. |

| ✅ Seek Expert Guidance | Consulting a door specialist ensures your choice fits your space, traffic level, and environmental needs. Expert advice guarantees lasting performance and better ROI for your facility. |

Choosing the right Industrial Impact Door ensures long-term reliability and smoother operations. Contact our experts today for personalized recommendations or a custom quote that fits your facility’s exact needs.

Frequently Asked Questions

FAQs: Common Questions About Industrial Impact Doors

What is an Industrial Impact Door used for?

An Industrial Impact Door is designed for high-traffic areas where equipment and workers move constantly. It helps prevent damage, reduce slowdowns, and maintain safe, efficient operations in warehouses, cold storage, and manufacturing facilities.

How is an Industrial Impact Door different from a regular swinging door?

Unlike standard swinging doors, the PE-Series Industrial Impact Doors feature reinforced panels and a two-way swing design that allow forklifts, carts, and staff to move freely without damaging the door or slowing workflow.

Can Industrial Impact Doors handle forklift and cart traffic?

Yes. Models like the PC-1500 forklift-rated impact door are built for constant use in busy zones. They absorb impact from forklifts and carts without bending or warping, helping reduce downtime and repair costs.

Are Industrial Impact Doors insulated for temperature control?

Absolutely. The PE-9000 Industrial Impact Door is engineered for cold-storage and temperature-controlled environments. Its insulated core and sealed frame help maintain consistent temperatures and energy efficiency.

Which model is best for a high-traffic warehouse?

For heavy-duty areas, the PC-1500 offers maximum strength and durability. For production lines with constant movement, the PE-8000 delivers a smooth swing that balances strength with flexibility.

Can Industrial Impact Doors help reduce energy costs?

Yes. Their insulated cores and tight seals minimize air exchange, helping maintain indoor temperatures. Over time, this can lead to significant energy savings in refrigerated or climate-controlled facilities.

How long do Industrial Impact Doors last?

With proper maintenance, Traffic Swinging Doors’ PE-Series and PC-Series doors can last up to five times longer than standard industrial doors, even in forklift-heavy environments.

Are Industrial Impact Doors USDA or OSHA compliant?

Yes. Many of our Industrial Impact Doors meet USDA and OSHA standards for safety, hygiene, and sanitation, making them suitable for food processing, packaging, and pharmaceutical environments.

Can these doors reduce noise in busy work areas?

Yes. Models like the PE-8000 include sound-dampening materials that help reduce noise in assembly lines, kitchens, and manufacturing floors, creating a more comfortable workspace.

Are Industrial Impact Doors customizable?

Yes. You can choose the size, color, material finish, and vision panel design to match your facility. Custom sizing is available for nonstandard openings or specialized environments.

Do these doors require electricity to operate?

No. All Industrial Impact Doors are manual and operate using balanced hinges and swing systems, ensuring dependable performance without motors or power requirements.

Can Industrial Impact Doors improve workplace safety?

Definitely. Each PE-Series model includes clear vision panels to improve visibility through hallways and production zones, reducing the risk of collisions in high-traffic areas.

Are these doors suitable for food and pharmaceutical facilities?

Yes. Our PE-9000 and PEX-9000 models feature smooth, nonporous surfaces and sealed frames that prevent moisture buildup, ideal for facilities requiring strict sanitation and cleanliness.

What materials are Industrial Impact Doors made from?

Most PE-Series doors use thermoplastic or ABS panels with foam or composite cores. These materials combine strength, flexibility, and resistance to cracking, making them ideal for demanding industrial use.

How should I maintain my Industrial Impact Door?

Clean the panels regularly, check hinges for alignment, and inspect seals every few months. Keeping your door maintained helps extend its lifespan and preserve smooth operation.

Are these doors resistant to moisture or rust?

Yes. Many PC-Series Industrial Impact Doors include stainless-steel hardware and rust-resistant components, perfect for washdown zones and facilities exposed to high humidity.

Can these doors be used outdoors or in partially open environments?

Yes, depending on the model. The PC-1500 and PE-9000 can withstand temperature fluctuations and moisture, making them suitable for loading docks, service bays, and semi-enclosed areas.

What’s the best Industrial Impact Door for medium-impact environments?

The PEX-9000 is ideal for medium-impact areas that experience frequent daily use. It’s lightweight yet durable, making it a great fit for retail stockrooms, maintenance zones, and general industrial applications.

Can I replace only one panel if it’s damaged?

In many cases, yes. Replacement panels and components are available for PE-Series and PC-Series doors, allowing quick repairs without replacing the entire frame.

How do I request a quote or get help choosing a door?

You can reach out to our team anytime for a free consultation. We’ll assess your facility layout, traffic flow, and environmental conditions to recommend the best Industrial Impact Door for your needs.

Photo Gallery

Strengthen Your Workflow with the Right Door

The right Industrial Impact Door keeps your facility running safely and efficiently. From the heavy-duty PC-1500 to the insulated PE-9000, each model is built for lasting reliability. Ready to upgrade your workflow? Explore our Industrial Impact Doors today and find the perfect fit for your operation.

Efficient Storage Design