Commercial Loading Docks Doors

Slow loading times, energy loss, and frequent door damage can interrupt daily operations. Commercial Loading Dock Doors are designed to solve these challenges by improving workflow, safety, and temperature control. In this guide, we’ll explain what makes these doors different, highlight top-performing models, and help you choose the best fit for your facility.

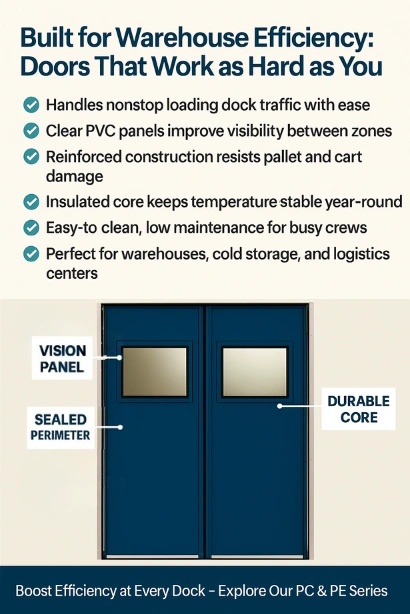

Designed for Heavy-Duty Commercial Use

The right Commercial Loading Dock Doors can completely transform how your facility operates. Whether it’s improving safety, reducing downtime, or keeping your environment temperature-controlled, PVC swinging doors offer performance you can count on. Explore our PC and PE Series models to find the best fit for your warehouse, manufacturing plant, or cold-storage facility, built for reliability, efficiency, and nonstop movement at your loading dock.

What Are Commercial Loading Dock Doors?

When your facility operates around the clock, every second counts. Loading dock doors face constant use, temperature changes, and equipment impact. That’s why businesses rely on Commercial Loading Dock Doors built for nonstop performance. These doors are made to handle continuous use while keeping work zones safe, efficient, and comfortable.

What Makes Them Different

Built for Continuous Movement

Commercial Loading Dock Doors are engineered for nonstop activity in fast-paced environments like warehouses, factories, and shipping centers. They’re designed to handle constant opening and closing without slowing operations.

Every component is built for endurance, making them ideal for facilities that depend on smooth, uninterrupted traffic flow throughout the workday.

Designed for Strength and Reliability

Unlike standard doors, these models swing in both directions to let forklifts and carts move freely. Reinforced panels absorb frequent impact without bending or cracking, maintaining dependable performance over time.

This durability keeps loading zones safe, efficient, and ready for heavy use in demanding commercial settings.

How They Support Better Facility Performance

Keeps Your Facility Efficient and Comfortable

Beyond strength and access, Commercial Loading Dock Doors help stabilize indoor temperatures and reduce energy loss between zones. Their insulated construction limits air exchange, helping maintain a comfortable workspace while lowering energy costs.

This efficiency is especially valuable for cold storage, food handling, and high-traffic environments that depend on climate control and steady performance.

Improves Safety and Everyday Workflow

Clear vision panels provide visibility between busy work areas, helping prevent accidents and collisions. Tight perimeter seals block dust and drafts, keeping dock zones cleaner and safer.

Together, these features make loading operations more efficient and dependable. Many facilities choose durable PVC swinging doors for lasting safety and reliable movement across their docks.

Top Recommended Door Models for Loading Docks

Every loading dock has different traffic levels, temperature needs, and workflow demands. Choosing the right door ensures long-lasting performance, safety, and energy efficiency. Below are four of our most trusted Commercial Loading Dock Door models, each designed to meet specific facility requirements and keep your operations running smoothly.

The PC-260 is built for nonstop movement in forklift-heavy environments. It delivers unmatched durability and visibility for facilities that can’t afford downtime or safety risks.

• Heavy-duty PVC panels withstand frequent impact from carts and forklifts.

• Clear vision panels improve visibility and reduce collisions during busy shifts.

• Reinforced hinges and frame ensure long-term, smooth operation.

• Ideal for large warehouses, logistics hubs, and high-traffic manufacturing docks.

PC-240 – For Mid-Impact and High-Visibility Zones

The PC-240 blends visibility and durability for operations that demand safety and awareness. It’s made to perform reliably in busy areas where clear sightlines and steady movement are critical.

• .240-inch PVC panels handle repeated use and moderate impact with ease.

• Transparent panels let workers see through both sides for safer navigation.

• Two-way swing keeps workflow efficient during high-traffic periods.

• Perfect for distribution centers and active commercial dock areas.

The PC-220 is a dependable, cost-effective choice for standard loading docks. It’s designed for businesses seeking long-lasting performance without the higher cost of heavy-duty options.

• Reinforced PVC construction stands up to everyday wear and light impact.

• Custom sizing ensures a proper fit for various dock layouts and openings.

• Two-way swinging access supports quick loading and unloading.

• A practical option for warehouses and general-use commercial facilities.

The PE-160 is built for facilities where climate control and cleanliness are priorities. It combines energy efficiency with dependable performance for balanced daily operations.

• Insulated PVC material reduces energy loss and stabilizes temperature zones.

• Tight perimeter seals prevent air leaks, dust, and debris intrusion.

• Smooth surfaces allow easy cleaning and low maintenance.

• Ideal for cold storage, food production, and climate-sensitive dock areas.

Commercial vs. Standard Industrial Doors

Choosing between Commercial Loading Dock Doors and standard industrial models often comes down to performance, durability, and long-term efficiency. While traditional doors handle basic operations, commercial PVC swinging doors are engineered for nonstop use, faster access, and better temperature control. The table below highlights how these options compare in key areas that matter most to busy facilities.

| Feature | Commercial Loading Dock Doors (PVC Swinging Type) | Standard Industrial Doors |

|---|---|---|

| Traffic Flow | Two-way swinging access keeps operations fast and efficient. | One-way or manual opening slows down workflow. |

| Durability | Reinforced PVC panels and heavy-duty hinges withstand constant impact from forklifts and carts. | Metal or wood panels often dent, warp, or rust under heavy use. |

| Energy Efficiency | Tight seals and insulated PVC reduce air loss and stabilize temperature zones. | Poor sealing leads to higher energy waste and uneven indoor climates. |

| Safety & Visibility | Clear panels improve line of sight, helping prevent accidents in high-traffic areas. | Opaque designs limit visibility and increase collision risks. |

| Maintenance | Low-maintenance construction with few moving parts, easy to clean and service. | Requires frequent lubrication, part replacements, and manual upkeep. |

| Customization | Available in multiple sizes and thicknesses across the PC and PE Series. | Limited sizing and material options for different facility types. |

| Best For | Warehouses, distribution centers, cold storage, and production facilities. | Light-duty or low-traffic operations. |

When compared side by side, Commercial PVC Swinging Doors clearly outperform standard industrial doors in nearly every category. They’re designed for today’s fast-paced work environments, helping you maintain safety, energy efficiency, and consistent productivity with less maintenance and downtime.

Choosing the Right Door for Your Facility

Selecting the right Commercial Loading Dock Door comes down to understanding how your facility operates. Each workspace has different needs based on traffic, temperature, and daily usage. By considering a few key factors, you can choose a model that improves workflow, minimizes maintenance, and delivers long-term efficiency.

| Factor | How to Decide & Recommended Models |

|---|---|

|

Traffic Level

Light, moderate, or heavy forklift activity |

|

|

Environment

Cold storage, food handling, or open dock zones |

|

|

Maintenance and Longevity

How often the doors are used and cleaned |

|

|

Budget and Efficiency Goals

When to invest for long-term ROI |

|

If your facility handles forklifts daily, upgrading to a PC-Series door can cut downtime and improve safety for years to come. Each model is designed to match your workflow, reduce maintenance, and keep your operations moving efficiently from one shift to the next.

Frequently Asked Questions

FAQs – Commercial Loading Dock Doors

What are the best Commercial Loading Dock Doors for busy warehouses?

Can PVC swinging doors like the PC-260 handle forklift impact?

How do I choose between PC-Series and PE-Series Commercial Loading Dock Doors?

Are Commercial Loading Dock Doors like the PE-160 energy efficient?

How long do Commercial PVC swinging doors last?

Can I order custom-sized Commercial Loading Dock Doors?

How often should I maintain my Commercial Loading Dock Doors?

Why choose swinging doors instead of roll-up doors for a loading dock?

Are PE-Series doors suitable for cold storage or freezers?

Where can I buy Commercial Loading Dock Doors for my business?

Can these doors fit into existing dock frames?

What materials are used in PC and PE Series doors?

Do all Commercial Loading Dock Doors include vision panels?

Can Commercial PVC doors help with noise reduction?

How do these doors improve worker safety?

Are Commercial Loading Dock Doors weather-resistant?

Are PVC swinging doors approved for food-handling environments?

Do your doors meet OSHA or safety compliance standards?

What color and finish options are available?

How long does installation take?

Photo Gallery

Streamline Your Dock Operations

The right Commercial Loading Dock Doors boost safety, efficiency, and energy savings across your facility. Our PC and PE Series models are built for long-term performance in demanding environments. Explore our doors or request a free quote today to keep your dock operations running smoothly.

Efficient Loading Dock Workflow