Egg Processing Station Swinging Doors

An egg processing plant runs quickly, with teams and equipment moving constantly between different work zones. This fast pace can create bottlenecks and increase the risk of contamination if areas are not well managed. Facilities need solutions that support both smooth movement and plant-wide cleanliness. This article explains how swinging doors help and how to choose the right model.

Engineered for Smooth & Sanitary Plant Operations

Industrial swinging doors play a key role in keeping egg processing plants efficient, clean, and safe. With hands-free movement, durable construction, and easy-to-clean materials, they help reduce slowdowns and support strict sanitation standards. Whether you manage a prep room, wash area, packing zone, or cold storage space, choosing the right swinging door makes daily operations smoother and more organized. Explore the PE-1500, PE-8000, PE-9000, and PEX-9000 to find the best fit for your workflow.

How Industrial Swinging Doors Improve Workflow and Sanitation in an Egg Processing Plant

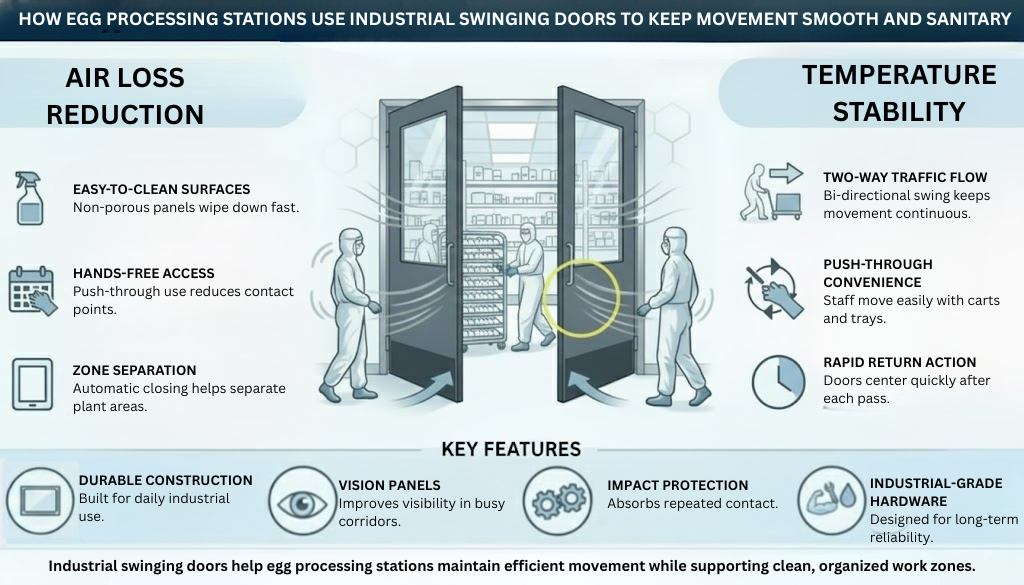

Industrial swinging doors support the fast pace of an egg processing plant by helping teams move between rooms without slowing down or affecting cleanliness. They keep movement consistent and make it easier to maintain organized work zones. Below are the key ways these doors improve workflow and sanitation throughout the facility.

How Two Way Swing Movement Reduces Traffic Slowdowns

How Two Way Swing Movement Keeps Traffic Moving

The two way swing lets workers and carts move through busy corridors without stopping, which helps prevent traffic from building up during peak hours. Since the panels open easily in either direction, staff can move through doorways with less effort and without waiting for someone to open the door ahead of them.

Why Automatic Closing Supports a Steady Workflow

After each pass, the door panels return to a closed position on their own. This helps maintain a consistent flow of movement across the plant and keeps pathways clear for the next person. With fewer interruptions and smoother transitions between rooms, daily activity stays steady even during demanding production cycles.

How Hands Free Access Supports Cleaner and Safer Workflows

How Hands Free Access Helps Maintain Cleaner Conditions

Hands free access reduces the need to touch handles, which helps lower surface contact in food production areas. Workers can move through doorways while carrying trays or equipment without breaking their focus. This supports a smoother workflow and helps maintain cleaner conditions as teams move between different tasks.

How Door Separation Supports Safer Plant Workflows

When the panels close automatically after each pass, they help separate prep, wash, packing, and storage zones. This makes it easier to maintain organized spaces and reduce the chance of cross contamination as products move through the plant. Clear separation also supports consistent sanitation routines across daily processing cycles.

Best Industrial Swinging Door Models for Egg Processing Plants

Every egg processing plant has its own layout, traffic levels, and equipment flow. The models below are chosen for how well they support real plant operations. Each one helps improve movement in specific areas while providing the durability and reliability needed for daily production.

The PE 1500 is well suited for prep rooms that experience steady but moderate movement. It supports smooth entry and exit for staff working throughout the day and is simple to maintain between cleaning cycles. Plants often choose it for rooms where reliable daily performance is important.

• Ideal for steady daily foot traffic

• Easy to clean between processing cycles

• Smooth and quiet movement

• Reliable option for standard prep rooms

PE 8000 for High Traffic or Temperature Controlled Rooms

The PE 8000 works best in busy areas or zones that rely on stable temperatures. Its durable build handles frequent use while helping maintain the room’s climate needs. It is commonly used in wash rooms, packing areas, and other spaces that run heavy traffic during production.

• Handles heavy daily movement

• Energy efficient for temperature sensitive rooms

• Durable for long hours of operation

• Strong choice for wash or packing areas

The PE 9000 is designed for high demand corridors where carts, trays, and equipment move throughout the day. It is built to withstand repeated impact and continuous activity, making it a dependable option during peak processing. Plants with fast paced workflows often rely on this model for its consistent performance.

• Built for constant door traffic

• Strong impact resistance

• Maintains performance under pressure

• Great for busy industrial corridors

The PEX 9000 is recommended for areas that require maximum durability and long term strength. Its reinforced construction supports heavier equipment flow and more demanding operations. Plants choose this model when they need a door that stays reliable even under intense daily use and challenging conditions.

• Reinforced for heavy duty needs

• Long lasting durability

• Handles larger equipment flow

• Best for demanding plant operations

Choosing the Right Door for Your Egg Processing Plant

Each area of an egg processing plant has its own traffic levels and equipment needs. The table below offers a simple side by side look at how each swinging door model performs in real plant settings. This quick comparison helps you choose the door that best matches your workflow requirements.

| Swinging Door Model | Best For | Traffic Level | Key Advantage | Why It Helps an Egg Processing Plant |

|---|---|---|---|---|

| PE 1500 | Standard prep zones | Medium | Easy to clean | Keeps daily movement smooth and sanitary |

| PE 8000 | Busy or temperature controlled rooms | High | Durable and energy efficient | Supports constant entry without slowing production |

| PE 9000 | Heavy equipment zones | Very High | Impact resistant | Handles nonstop cart and tray movement |

| PEX 9000 | Reinforced industrial environments | Very High | Extra strength | Reliable for demanding operations |

This table gives you a clear overview of how each model supports different parts of your plant. Whether you need a door for steady prep room activity or high demand corridors with nonstop equipment flow, choosing the right model ensures smoother movement and dependable performance. Up next, we will look at how to match these options to your specific plant layout and daily routine.

How to Choose the Right Swinging Door for Your Egg Processing Plant

Choosing the right swinging door makes a noticeable difference in how smoothly your plant operates each day. Since every facility has different traffic patterns, cleaning routines, and equipment flow, it helps to look closely at what each area needs before deciding. The points below guide you through the most important factors to consider.

| Factor to Evaluate | Why It Matters in Egg Processing Plants |

|---|---|

| ✓ Traffic levels across each room | Knowing how often workers and carts pass through a doorway helps you choose a swinging door that can keep up with daily use without wearing out or slowing movement during busy periods. |

| ✓ Cleaning and sanitation routines | Different zones require different washdown schedules. Matching the door surface and build to your cleaning routine helps keep each area easier to maintain and supports consistent sanitation standards. |

| ✓ Equipment size and weight | Considering the carts, trays, and other equipment moving through the opening ensures the door has the durability and clearance needed to handle daily impact without damage or extra strain. |

| ✓ Workflow and safety needs | Choosing the right model helps keep pathways clear and plant zones organized, which supports smoother production flow and safer transitions between stages of egg processing. |

| ✓ Unique layouts and custom sizing | Custom sizing or configurations help doors fit tight corridors, wider openings, or irregular layouts so each part of the plant gets a swinging door that matches how the space is actually used. |

By evaluating these factors before choosing a swinging door, you ensure that every area of your egg processing plant gets the right level of support. The right fit keeps movement steady, strengthens sanitation routines, and helps your entire operation run with greater efficiency and confidence.

Frequently Asked Questions

FAQs About Industrial Swinging Doors in Egg Processing Plants

Are industrial swinging doors safe for egg processing plants?

Yes. Industrial swinging doors are designed for food production environments and support safe movement by reducing contact points, separating work zones, and maintaining cleaner pathways throughout the plant.

Do swinging doors help prevent contamination between plant zones?

Yes. Their automatic closing and hands free access help limit cross contact and keep prep, wash, packing, and storage areas more controlled during daily operations.

What swinging door model works best for high traffic egg processing corridors?

Many plants choose the PE 9000 because it handles nonstop cart and tray movement with strong impact resistance and consistent performance in fast paced areas.

Which swinging door is best for temperature controlled rooms in an egg processing plant?

The PE 8000 is a reliable choice for climate sensitive zones because its durable build helps maintain stable room conditions while supporting frequent entry.

Are swinging doors durable enough for heavy carts and equipment?

Yes. Models like the PE 9000 and PEX 9000 are built to withstand repeated impact and constant equipment flow, making them suitable for high demand plant corridors.

Can industrial swinging doors handle constant sanitizing and washdowns?

Yes. These doors are made with materials and hardware suited for routine sanitation, allowing them to hold up well during frequent cleaning cycles.

Which swinging door is best for medium traffic prep rooms?

The PE 1500 works well for steady daily movement in prep areas where staff need smooth entry and easy cleaning between processing tasks.

What type of swinging door should we use for heavy duty zones with large equipment?

The PEX 9000 is often selected for reinforced environments because it offers long term strength for areas with heavier machinery and demanding workflows.

Are swinging doors customizable for unique plant layouts?

Yes. Most models, including the PE 1500 and PE 8000, can be customized in size, vision panels, bumpers, and material options to match your facility requirements.

How long do industrial swinging doors typically last in an egg processing plant?

With proper use and regular sanitation, well built models like the PE 9000 and PEX 9000 provide long service life, even under daily industrial pressure.

Do swinging doors help reduce slowdowns during peak production hours?

Yes. The two way swing and automatic closing help teams move quickly without stopping, which reduces bottlenecks in busy hallways.

Are these doors suitable for cold storage or chilled rooms?

Yes. The PE 8000 is especially effective for chilled or temperature sensitive areas because it supports energy efficiency and consistent climate control.

Can swinging doors improve worker safety in tight or busy spaces?

Yes. Vision panel options and hands free movement help workers see incoming traffic and avoid collisions in narrow corridors or fast moving zones.

Do egg processing facilities need different door models for different rooms?

Often, yes. Prep rooms may use the PE 1500, while high traffic corridors perform better with the PE 9000, and heavy duty zones rely on the PEX 9000.

How well do swinging doors hold up during long production shifts?

Industrial models are built for continuous use. Doors like the PE 9000 maintain smooth movement and durability even during nonstop traffic.

Do swinging doors help maintain cleaner workflows during egg handling?

Yes. Hands free entry reduces surface contact and helps teams move through rooms without interrupting sanitation practices.

Can swinging doors reduce noise in busy plant areas?

Yes. Many models are designed to close quietly and minimize disturbances, helping maintain a more controlled working environment.

Are replacement parts available for long term maintenance?

Yes. Most industrial swinging doors, including the PE series, offer replaceable bumpers, hinges, and vision panels for ongoing upkeep.

Can we install swinging doors in older or retrofitted plant facilities?

Yes. These doors can be adapted to a wide range of doorway sizes, making them suitable for both new plants and existing structures.

Which door offers the most strength for demanding egg processing operations?

The PEX 9000 provides reinforced construction and long term durability, making it ideal for areas that take repeated impact or require maximum structural reliability.

Photo Gallery

Choosing the Swinging Door That Fits Your Facility

Industrial swinging doors give egg processing plants a practical way to support smoother daily routines by matching each work area with a door built for its specific demands. When the right model is selected, teams can move through their shifts with greater confidence and fewer interruptions. If you are considering options such as the PE 1500, PE 8000, PE 9000, or PEX 9000, we can help you compare their strengths and choose the one that fits your facility’s needs best.

Efficient Egg Processing Workflow