Factory Room Swinging Doors

Bottlenecks are a common issue inside factory rooms where people, carts, and equipment move through shared access points. This article explains why these slowdowns occur, where they typically form, and how access points affect production flow. It also outlines common use areas, compares door options, and answers key questions to help factories improve internal movement.

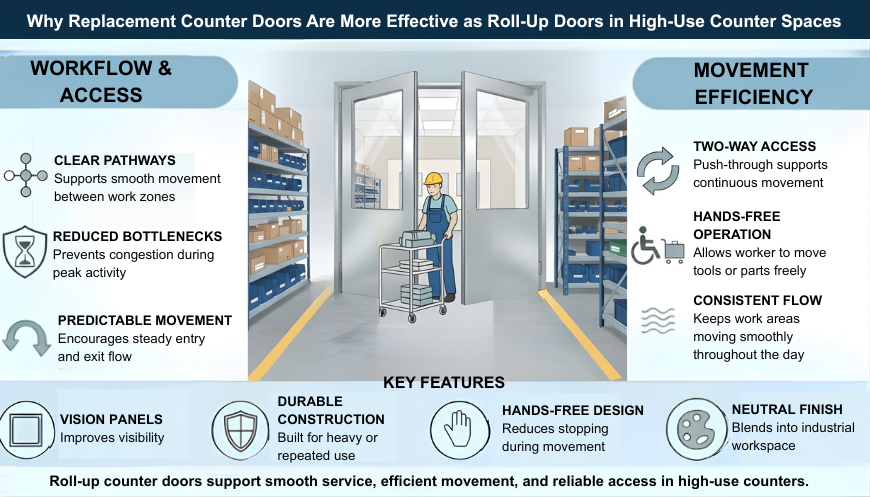

Engineered for Industrial Workflow and Movement

Bottlenecks on the production floor often start at access points inside factory rooms. When people, carts, and equipment are forced to slow down or stop, productivity and safety suffer. Swinging doors help eliminate these delays by allowing smooth, two-way movement without interrupting workflow. By matching the right swinging door to traffic levels, factories can keep operations moving efficiently while reducing congestion in high-use areas.

Why Bottlenecks Form Inside Factory Rooms

After knowing bottlenecks as a common production floor issue, it helps to understand why they occur so frequently inside factory rooms. In most facilities, congestion develops where space is limited and movement is constant. These conditions make access points especially vulnerable to slowdowns.

Where Congestion Typically Builds Inside Factory Rooms

Common Factory Room Areas Where Congestion Starts

Congestion most often appears at entrances to production rooms, internal transfer areas, storage access points, and corridors that connect multiple work zones. These locations naturally carry high traffic because they link different stages of work. Throughout the day, people, carts, and equipment move through these spaces repeatedly, increasing the chance of delays.

Why These Areas Become Bottlenecks During Busy Periods

During peak activity, even brief pauses at these access points can quickly build into larger backups. When movement is forced to slow or stop, congestion spreads into nearby areas and affects surrounding tasks. What begins as a small delay can quickly disrupt the rhythm of the production floor.

How Access Points Slow Movement and Affect Operations

How Traditional Doors Disrupt Movement at Access Points

Traditional doors and narrow openings often require people and equipment to stop, wait, or reposition before passing through. These repeated interruptions break the natural flow of movement and make traffic patterns uneven, especially in factory rooms with frequent back-and-forth activity.

How These Slowdowns Affect Safety and Production Flow

As movement becomes less predictable, the risk of collisions increases and productivity begins to drop. Delays at access points can ripple across connected work zones, reducing overall throughput. In factory rooms where timing and coordination matter, these slowdowns make it harder to maintain steady and efficient operations.

Swinging Door Options That Help Reduce Bottlenecks

Not all factory rooms experience the same type of traffic. Some areas support steady employee movement, while others handle carts, pallets, or equipment moving continuously throughout the day. Matching swinging doors to how each space is actually used helps prevent slowdowns without overcomplicating daily operations.

Some factory rooms experience steady movement throughout every shift without heavy equipment use. This option is designed for areas where access points stay active but controlled.

• Ideal for factory rooms with regular pass-through activity

• Handles repeated movement from people and carts across shifts

• Helps maintain predictable flow in consistently active areas

PE-8000 for High-Traffic Factory Rooms with Separation Needs

Busy factory rooms often require access solutions that manage movement while keeping work zones clearly defined. This option fits environments where traffic is frequent and separation still matters.

• Used in factory rooms where movement is frequent and ongoing

• Supports access while maintaining separation between work zones

• Helps keep traffic organized in busy production environments

Factory rooms with constant equipment movement place greater demands on access points. This option is suited for areas where traffic rarely slows and durability is critical.

• Suited for factory rooms with forklifts and pallet movement

• Performs well in areas with constant transfers and equipment use

• Helps prevent congestion during peak production activity

Factory rooms with lighter internal movement still need access points that keep people moving without interruption. This option fits spaces where traffic is frequent but impact demands remain low.

• Well suited for factory rooms with frequent employee movement

• Supports consistent access between work areas without interruption

• Fits spaces where traffic is steady but impact levels remain low

Swinging Doors for Factory Rooms

Choosing the right swinging door for your factory room can be challenging with so many traffic conditions and access needs. This quick comparison helps you see which option fits each type of factory room, so you can make a faster, more confident decision without reading through all the details.

| Swinging Door Model | Best Fit for Factory Rooms With | Typical Traffic Level | Common Use Areas |

|---|---|---|---|

| PEX-9000 | Light internal movement | Light to moderate | Prep rooms, interior corridors, secondary access points |

| PE-1500 | Steady daily pass-through | Moderate | Stockrooms, packaging areas, internal transfer rooms |

| PE-8000 | Frequent movement with separation needs | High | Busy production rooms, controlled work zones |

| PE-9000 | Continuous equipment movement | Very high | Forklift routes, pallet traffic zones, 24-hour operations |

You can quickly see which swinging door aligns with traffic patterns and room requirements, making it easier to select the right solution for each part of your factory without slowing down your workflow.

Key Features That Make Swinging Doors Effective

Factory rooms need access solutions that keep traffic moving efficiently while protecting equipment and staff. The right swinging door combines durability, safety, and hygiene features to ensure smooth operations even in high-use areas. Here’s a quick look at the features that matter most for factory rooms:

| Feature | Why It Matters |

|---|---|

| ✅ Full-Perimeter Seals for Hygiene and Temperature Control | Helps maintain clean, climate-controlled environments by minimizing air exchange and keeping out contaminants, ideal for cold rooms and prep zones. |

| ✅ Tear-Drop Bumpers and Kick Plates | Protects the door surface from frequent impact by carts or boots, reducing long-term damage and extending service life. |

| ✅ Rust-Resistant Hardware for Washdown Zones | Built for sanitation routines, stainless components resist corrosion from frequent high-pressure cleaning and moisture exposure. |

| ✅ Clear Vision Panels to Reduce Collisions | Enhances safety in busy corridors by providing visibility through the door, especially helpful in high-traffic, fast-paced processing areas. |

| ✅ Durable Foam or ABS Cores That Hold Up Under Stress | These industrial-grade cores are engineered for durability under constant pressure, making them ideal for facilities where doors take repeated impact and still need to perform. |

Using these features strategically helps factories reduce bottlenecks, protect staff and equipment, and maintain consistent flow throughout the production floor. By selecting swinging doors with the right combination of seals, bumpers, hardware, visibility, and core materials, operations stay safer and more efficient day after day.

Frequently Asked Questions

FAQs About Swinging Doors in Factory Rooms

Why are swinging doors used instead of traditional doors in factory rooms?

Swinging doors, like the PE-1500 and PE-9000, allow two-way movement without stopping workflow. They reduce bottlenecks and make internal traffic safer and more efficient than single-swing or sliding doors.

Which swinging doors work best for high-traffic factory areas?

High-traffic corridors and production rooms benefit most from the PE-8000 or PE-9000 heavy-duty swinging doors, designed to handle continuous staff and equipment movement without slowing operations.

Can swinging doors handle forklifts, carts, or pallet jacks?

Yes, especially the PE-9000. Its reinforced construction supports heavy equipment and repeated impact, keeping workflows smooth and minimizing wear over time.

How do I determine which swinging door suits my factory room?

Consider traffic levels, type of movement, and room size. Light traffic fits PEX-9000, moderate traffic matches PE-1500, and heavy or equipment-intensive areas use PE-8000 or PE-9000.

Are swinging doors suitable for storage and inventory areas?

Yes. PEX-9000 and PE-1500 models work well in storage and inventory access points, allowing staff to move items quickly without creating congestion.

Do swinging doors improve safety in busy factory corridors?

Doors with features like clear vision panels, soft-return hinges, and bumpers, available in PE-1500 and PE-9000, reduce collisions and help staff navigate safely.

Can swinging doors maintain temperature or environmental control?

Yes, models with full-perimeter seals, such as PE-8000, help maintain temperature control and minimize air exchange, ideal for prep zones or cold storage rooms.

Are swinging doors easy to clean for factory environments?

Yes. Industrial-grade surfaces on PEX-9000 and PE-1500 doors are easy to wipe down, supporting hygiene requirements without extra maintenance effort.

How often should swinging doors be maintained?

Heavy-duty doors like PE-9000 require periodic checks of hinges, seals, and bumpers every few months depending on traffic, while lighter models may need less frequent maintenance.

Can swinging doors be customized for specific factory needs?

Yes. Many models allow options for vision panels, colors, and door sizes to match traffic, workflow, or safety requirements.

Do swinging doors reduce bottlenecks during peak shifts?

Yes. PEX-9000 through PE-9000 doors enable continuous two-way movement, preventing slowdowns even during peak factory activity.

Are heavy-duty swinging doors durable for long-term industrial use?

PE-8000 and PE-9000 doors are built with reinforced cores and impact-resistant hardware to withstand repeated use and heavy equipment contact.

Can swinging doors be installed in narrow corridors?

Yes, all swinging doors are designed to swing both ways, allowing installation in tighter corridors without blocking traffic flow.

Do employees need training to use swinging doors?

No, these doors are intuitive. Staff can push through normally, and the door swings both ways automatically, making them easy for everyone to use.

How do I choose between PEX-9000 and PE-1500 for moderate traffic areas?

PEX-9000 is best for light traffic zones, like prep or secondary rooms, while PE-1500 suits moderate daily use areas like packaging or stockrooms.

Can swinging doors handle continuous heavy equipment movement?

Yes, the PE-9000 is designed for continuous operation in areas with forklifts and pallets, preventing slowdowns even under high impact.

Are swinging doors suitable for temperature-sensitive production rooms?

Yes. PE-8000 doors with insulated cores and full-perimeter seals protect environmental zones while still allowing smooth traffic flow.

Do swinging doors help maintain organized workflow?

Yes. By allowing uninterrupted movement, PE-1500 and PE-9000 doors reduce cross-traffic, making work zones more predictable and easier to manage.

Can swinging doors help reduce noise in high-traffic areas?

Partially. Smooth operation and tight seals reduce the sound of repeated openings and closings compared to traditional doors, improving the work environment.

Are swinging doors a good investment for long-term factory efficiency?

Yes. Investing in doors like PE-8000 or PE-9000 helps prevent bottlenecks, protect equipment, and maintain consistent flow, enhancing productivity and safety over time.

Photo Gallery

Streamline Your Factory Flow with Swinging Doors

Bottlenecks in factory rooms can slow operations, disrupt workflow, and affect productivity, especially in areas where staff, equipment, and materials intersect. Swinging doors provide a practical, proven solution by allowing smooth, two-way movement and reducing interruptions, helping high-traffic zones, storage areas, and production corridors operate efficiently. By evaluating traffic flow and matching doors to each space’s actual usage, factories can maintain safer, more organized, and consistently efficient operations throughout the day.

Efficient Material Movement