Maintenance Shop Swinging Doors

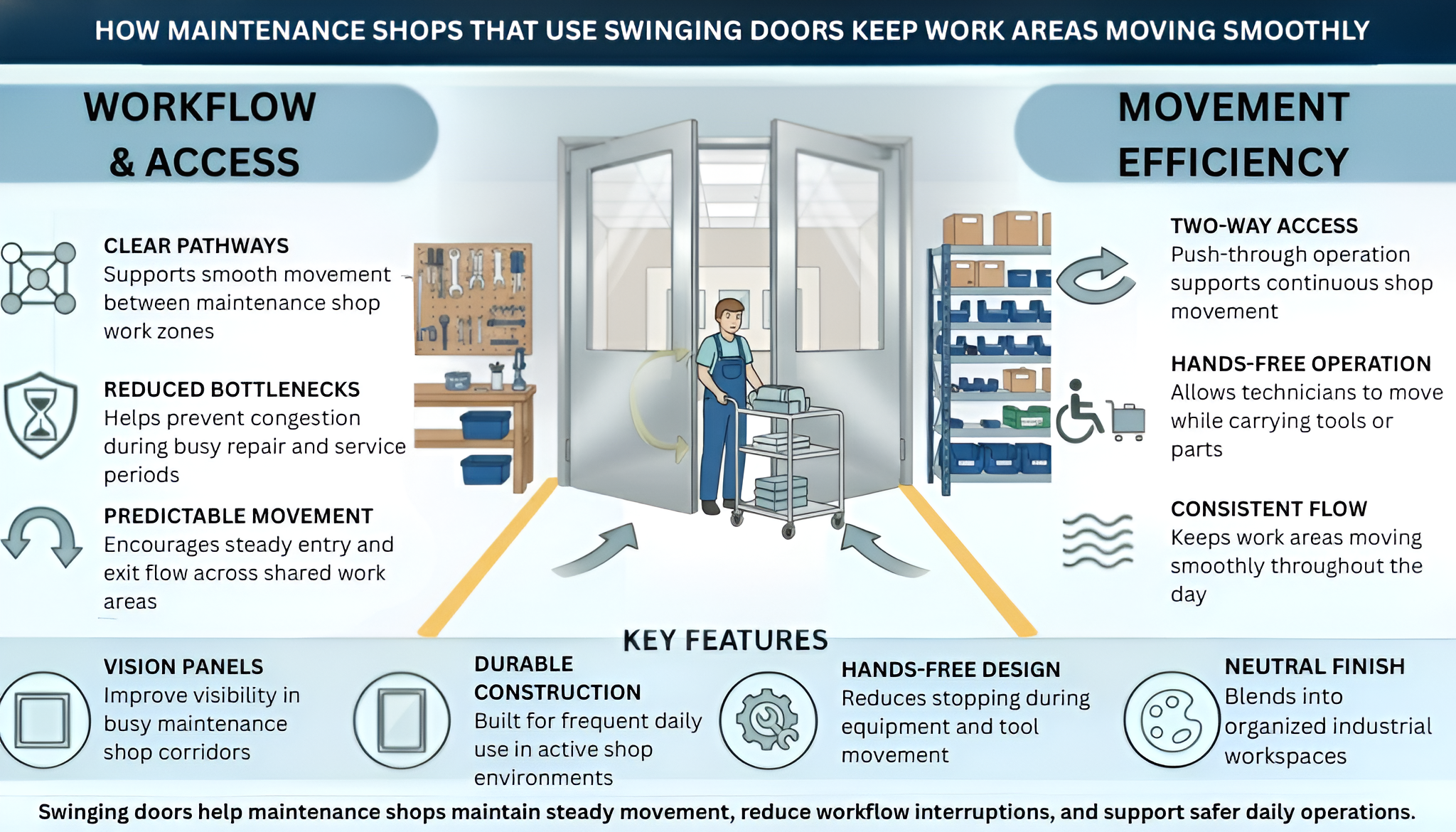

Maintenance shops depend on constant movement between work areas. Tools, carts, equipment, and staff are always in motion, yet doorways often disrupt that flow. This page explores where movement breaks down, how shop layouts contribute to delays, and why swinging doors are commonly used to support smoother daily operations.

Designed for Non-Stop Shop Movement

Maintenance shops rely on smooth movement to stay productive. When tools, carts, and equipment are constantly in motion, even small delays can slow the entire workflow. Swinging doors help reduce bottlenecks by allowing hands-free, two-way access between busy work areas. By keeping traffic moving naturally, these doors support safer movement, better efficiency, and fewer interruptions throughout the day, especially in high-traffic service and back-of-house zones.

Why Movement Breaks Down in Busy Maintenance Shops

Even well-organized maintenance shops can experience movement issues once activity increases. These slowdowns are not usually caused by poor planning. They develop when multiple tasks overlap and shared pathways are used more frequently throughout the day.

Doorways Become Pressure Points During Peak Activity

Doorways Attract Multiple Movements at Once

As activity picks up, doorways become natural convergence points. Technicians, carts, and equipment often reach the same opening at the same time. Brief pauses become unavoidable as people wait for space to clear, especially during busy periods when movement remains constant.

Small Pauses Disrupt Momentum Across Work Areas

When these stops happen repeatedly, overall momentum begins to fade. A short delay at one doorway can slow nearby tasks and interrupt workflow. Over time, these interruptions create friction that makes efficient work areas feel less fluid.

Transitions Between Work Zones Create Hidden Delays

Transitions Between Work Zones See Constant Back-and-Forth

Movement also slows where service bays connect to storage or prep areas. These transition points handle steady back-and-forth traffic throughout the day. When tasks overlap, technicians and carts converge in the same space, increasing the chance of brief slowdowns.

Hands-Full Movement Makes Interruptions More Disruptive

Technicians frequently move while carrying tools or parts. Stopping in these moments breaks rhythm and focus. As traffic stacks up, interruptions repeat and compound, making busy maintenance shops feel tighter and more crowded than they truly are.

Swinging Door Options That Support Maintenance Shop Workflow

Once movement challenges are identified, choosing the right swinging door comes down to matching each work area with the level of traffic it handles. Different zones move at different speeds, and selecting the right door helps keep work areas functioning without added friction.

The PE-620ALC is a practical option for areas where movement is steady but controlled. It fits spaces that need reliable access without constant heavy equipment passing through.

• Supports steady movement in areas with predictable activity

• Helps staff move between tasks without disrupting nearby work

• Fits zones where smooth transitions matter more than volume

PE-710 for Everyday Shop Movement

The PE-710 is designed for day-to-day shop traffic where consistency matters most. It works well in areas that see regular foot and cart movement throughout the workday.

• Handles routine foot and cart traffic with ease

• Keeps common pathways moving without slowing daily tasks

• Works well between frequently used work areas and storage zones

The PE-720 is suited for busier sections of a maintenance shop where activity rarely slows down. It supports areas that experience frequent movement from both staff and equipment.

• Supports higher traffic levels in shared access points

• Helps reduce interruptions during frequent equipment movement

• Fits zones where repeated activity impacts overall workflow

The PE-8000 is intended for industrial sections of maintenance shops with wide openings and continuous movement. It fits environments where uninterrupted access is essential to keeping operations on schedule.

• Designed for wide openings with sustained daily movement

• Supports larger equipment moving through active shop areas

• Fits zones where reliable access is critical to productivity

How Swinging Doors Improve Movement in Maintenance Shop Work Areas

After matching door options to different shop zones, it helps to see how swinging doors support movement in everyday situations. This table highlights common work area challenges and shows how swinging doors help keep activity moving without interrupting daily routines.

| Maintenance Shop Situation | Common Problem Without Swinging Doors | How Swinging Doors Help |

|---|---|---|

| Tool and equipment transport | Staff must stop to open doors | Allows hands-free movement while carrying tools or parts |

| Cart traffic between work zones | Carts slow down or pile up at openings | Supports smooth two-way movement between areas |

| Transitions between service bays | Bottlenecks form during busy periods | Keeps traffic flowing when tasks overlap |

| Prep or wash area entry points | Doors are left open or slammed shut | Returns to position without disrupting movement |

| High-use corridors | Frequent stops cause wear and delays | Handles constant daily traffic more smoothly |

This quick comparison shows how swinging doors remove friction from common maintenance shop scenarios, helping work areas stay connected and movement stay consistent throughout the day.

Where Swinging Doors Make the Biggest Difference in a Maintenance Shop

After knowing how swinging doors support daily movement, placement becomes the deciding factor. Installing them in the right locations helps maintain steady workflows and prevents small interruptions from spreading across the shop.

| Placement Area | Why It Matters in Maintenance Shops |

|---|---|

| ✔ Between service bays and parts storage | Supports repeated back-and-forth movement and helps technicians move between work and parts access without unnecessary slowdowns. |

| ✔ Entry points to wash or prep areas | Keeps movement steady while helping separate work zones, so staff can move in and out without breaking pace during busy periods. |

| ✔ Back-of-house corridors | Helps reduce stop-and-go movement in common passageways that connect multiple work areas, which can prevent congestion from spreading. |

| ✔ Equipment pathways | Supports smoother movement for carts and larger items by reducing the need to stop, reposition, or wait at key openings. |

When placed in the right locations, swinging doors work quietly in the background to support smoother movement, better coordination, and more predictable workflows across the entire maintenance shop.

Frequently Asked Questions

FAQs About Swinging Doors in Maintenance Shops

Are swinging doors a safe option for busy maintenance shops with constant traffic?

Yes. Swinging doors are commonly used in active maintenance shops because they support steady movement without forcing sudden stops in shared work areas.

Can swinging doors handle carts and equipment moving through a maintenance shop?

They are designed for environments where carts and equipment move frequently between work zones, making them well suited for daily shop traffic.

Which swinging door works best for moderate traffic areas in a maintenance shop?

For areas with steady but controlled movement, options like the PE-620ALC are often chosen to support smooth transitions without overbuilding the space.

What swinging door is best for everyday foot and cart traffic?

In common shop pathways with regular movement, doors such as the PE-710 are typically used to support consistent daily access.

Are there swinging doors designed for heavy-use shop areas?

Yes. In busier sections where equipment movement is frequent, models like the PE-720 are commonly selected to support higher activity levels.

Which swinging doors are used in industrial sections of maintenance shops?

For wide openings and constant activity, industrial options like the PE-8000 are often used to support uninterrupted movement.

Where should swinging doors be installed in a maintenance shop layout?

They are most effective between service bays and storage areas, at wash or prep entry points, along back-of-house corridors, and in equipment pathways.

Do swinging doors help technicians move more efficiently during busy periods?

They support continuous movement by reducing the need to stop and manage doors when moving between tasks.

Are swinging doors suitable for narrow corridors in maintenance shops?

Yes. They are often used in corridors where space is limited and smooth transitions between connected areas are important.

Can swinging doors be added to an existing maintenance shop?

Swinging doors are commonly integrated into existing openings without requiring major layout changes.

Do swinging doors require special training for shop staff?

No. They operate naturally, allowing staff to move through openings without learning new procedures.

How do swinging doors hold up under daily maintenance shop use?

They are built for frequent, repeated use in active environments where doors are opened and closed throughout the day.

Can swinging doors support both foot traffic and carts at the same time?

Yes. They are designed to accommodate mixed movement, which is common in maintenance shop workflows.

Are swinging doors appropriate near wash or prep areas?

They are commonly installed at these entry points to support frequent in-and-out movement while keeping spaces clearly defined.

Do swinging doors help reduce congestion in shared work areas?

By supporting predictable movement patterns, they help minimize backups near busy openings.

Will swinging doors interfere with visibility between work zones?

Many maintenance shops choose configurations that maintain awareness while still separating spaces as needed.

Are swinging doors noisy in active shop environments?

They are designed for controlled movement, which helps reduce disruptive noise from repeated opening and closing.

Can swinging doors support growing maintenance shops with increasing traffic?

As shop activity increases, choosing doors designed for higher use can help support smoother movement without reworking the entire layout.

How do I choose the right swinging door for different shop areas?

The best approach is matching door options to traffic levels, from moderate-use areas to heavy and industrial zones.

Are swinging doors a practical long-term upgrade for maintenance shops?

Yes. Many shops choose them as a scalable solution that supports daily movement as operations evolve.

Photo Gallery

Supporting Smooth, Reliable Movement Across the Shop

Smooth movement plays a direct role in how efficiently a maintenance shop operates each day. When work areas stay connected and traffic flows naturally, teams can focus on tasks instead of navigating interruptions. Swinging doors help remove everyday friction by supporting consistent access between zones without disrupting activity. Choosing the right door for each area allows shops to maintain safety, comfort, and workflow as demands change, making daily operations more predictable and easier to manage over time.

Maintenance Shop Workflow