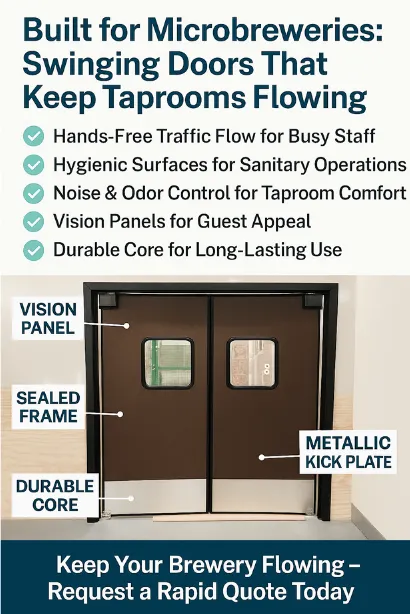

Microbreweries Swinging Doors

Swinging doors help microbreweries separate taproom and production areas without slowing staff. They support smooth traffic flow, cleaner workspaces, and a more comfortable guest experience. This article explains why these doors are essential in brewery design, highlights the best door models for specific needs, and shares tips on choosing the right fit.

Designed for Heavy-Duty Brewery Use

Swinging doors are more than a convenience, they’re an essential part of brewery design. The right doors improve staff efficiency, maintain hygiene, and create a polished experience for guests. Whether you need premium finishes for guest-facing areas, durable panels for heavy cart traffic, or insulated models for cold storage, there’s a swinging door solution that fits your layout. Explore the options and see how they can help your brewery flow as smoothly as your taps.

Why Swinging Doors Solve Brewery Traffic and Separation

In a busy microbrewery, it is not enough to simply divide taproom and production spaces. The real challenge is making both areas work together without disrupting staff or guests. Swinging doors address this by managing the flow of people, reducing disruptions, and helping customers feel connected to the brewing process in a safe way.

Smooth Operations for Staff

Easier Movement During Rush Hours

When weekends get hectic, servers often weave through narrow hallways with trays of drinks or staff roll heavy kegs toward storage. Swinging doors keep everyone moving by eliminating the need to stop and grab a handle. This reduces hallway collisions, prevents long wait times, and helps employees keep pace with customer demand.

Cleaner and Safer Brewing Areas

Brewing zones are prone to spills, splashes, and equipment mess. Swinging doors act like a barrier that keeps these issues from spilling into the taproom where guests gather. By containing the mess where it belongs, they allow public areas to stay tidy and professional, while production staff focus on brewing without interruption.

Comfort and Experience for Guests

A Quieter, More Comfortable Taproom

Taprooms thrive on lively conversation, not the clatter of kegs or the hum of machinery. Swinging doors soften these sounds and minimize the strong scents of hops or fermentation. Guests can relax, enjoy their drinks, and feel at ease, while the production process continues just steps away behind the doors.

Transparency Without the Risks

Guests love to feel connected to the craft, and vision panels make that possible. Customers can peek through the windows to see brewers at work without stepping into restricted zones. This creates a unique sense of authenticity, giving visitors a closer look at the brewing process while keeping them safe and comfortable in the taproom.

Best-Fit Door Models for Microbreweries

Every brewery has unique spaces, from guest-facing taprooms to heavy-use back areas. Choosing the right swinging door means finding the best fit for where it will be installed. Below are four models designed to meet the demands of different brewery environments.

When style matters as much as performance, the PE-620ALC is the door to trust. It is designed to enhance customer-facing spaces while holding up to constant movement between taproom and production.

• Brushed aluminum finish creates a professional, upscale appearance.

• Solid wood core construction provides lasting durability.

• Customizable sizing adapts to various taproom and brewhouse entrances.

• Perfect for behind-the-bar access where both style and performance matter.

Brewery hallways and storage routes take a beating from kegs, carts, and equipment. The PE-710 was built for these conditions, keeping service routes fast and reliable.

• Lightweight honeycomb polymer core keeps movement smooth and efficient.

• Built to withstand constant bumps from carts and brewing equipment.

• Custom sizing available for narrow hallways or storage access points.

• Ideal for high-traffic service routes where speed and resilience are critical.

Breweries often need a dependable door that works across multiple areas. The PE-720 is that flexible choice, balancing cost-effectiveness with everyday reliability.

• Made from durable ABS plastic that is simple to clean.

• Fits a wide variety of openings across the brewery floor.

• Cost-effective while still built for everyday performance.

• Works well for connecting taprooms, prep zones, or production areas.

PE-8000: Built for Cold and Heavy-Duty Zones

Some brewery spaces require extra strength and insulation, especially around keg storage and cooler entrances. The PE-8000 is engineered for these demanding environments.

• Industrial-grade build stands up to heavy foot traffic and impact.

• Insulated design helps maintain cooler temperatures.

• Strong PVC frame and core materials provide long-term reliability.

• Ideal for walk-in coolers, keg storage, and high-impact back-of-house zones.

Brewery Swinging Doors at a Glance

Choosing the right door is easier when the options are compared side by side. While each model offers unique strengths, this table gives a clear snapshot of where each one fits best in a brewery setting.

| Door Model | Best Brewery Use Case | Core Strengths | Sizing Options | Guest-Facing Appeal |

|---|---|---|---|---|

| PE-620ALC | Taproom ↔ Brewhouse (behind bar) | Wood core, brushed aluminum finish, strong durability | Up to 96″ × 96″ | ✔ High |

| PE-710 | Service corridors, cart and keg traffic | Honeycomb core, reinforced edges, impact resistance | Up to 48″ × 96″ | Moderate |

| PE-720 | General taproom to production | ABS core, easy to clean, versatile across brewery areas | Up to 96″ × 96″ | Moderate |

| PE-8000 | Cold storage & heavy back-of-house | Industrial ABS + PVC frame, USDA accepted, insulated | Up to 96″ × 120″ | ✖ Low |

Beyond comparing models, breweries can also tailor doors to better suit daily operations. From impact protection to sanitation-friendly upgrades, the right accessories often extend the life of the door and improve safety. Next, let’s look at the add-ons and checklist that help customize these doors to fit your exact layout.

Add-Ons and Selection Checklist

Once you’ve identified the right door model, the next step is tailoring it to fit your brewery’s unique needs. Add-ons and smart choices can extend the life of the door, improve safety, and make daily operations easier.

| Feature | Why It Matters in Breweries |

|---|---|

| ✔ Bumpers | Absorb hits from kegs and carts to prevent dents and cracks, reducing maintenance and extending door life in high-traffic routes. |

| ✔ Kick Plates | Reinforce the lower door area where staff push with boots or carts, keeping panels clean and presentable in guest-adjacent pathways. |

| ✔ Window Options | Clear vision panels improve sightlines at busy crossings to reduce collisions, while letting guests safely view the brewing action. |

| ✔ Perimeter Seals | Help maintain stable conditions in cooler rooms and prep areas by reducing air exchange and minimizing odor transfer. |

| ✔ Steel Frames | Provide rigid support for high-use openings and withstand wash-down routines, keeping doors aligned and operating smoothly over time. |

Add-ons and thoughtful choices can turn a standard swinging door into a perfect fit for your brewery’s workflow. From safety features to temperature control, these upgrades ensure the doors work as hard as your staff. With the basics and enhancements in place, the next step is addressing the common questions breweries often have before making a decision.

Frequently Asked Questions

FAQs – Swinging Doors in Microbreweries

How do microbreweries use swinging doors to separate production from taproom traffic?

Microbreweries use swinging doors like the PE-720 versatile ABS door or the PE-710 honeycomb core door to divide production areas from guest spaces. These doors allow staff to move trays and kegs hands-free while blocking noise and odors, creating a clean taproom experience with optional windows for guest visibility.

Can swinging doors help keep brewing areas sanitary?

Yes. Doors like the PE-720 versatile ABS swinging door create a barrier that contains spills and brewing mess in production areas while keeping taprooms neat and welcoming.

Can brewery swinging doors be used for cooler entrances?

Absolutely. The PE-8000 industrial swinging door is insulated and USDA-accepted, making it ideal for walk-in coolers and keg storage zones.

Are swinging doors easy to use when carrying trays or kegs?

Yes. Models such as the PE-710 lightweight honeycomb swinging door open hands-free with a push, allowing staff to move quickly during peak service.

Can I add windows safely to brewery swinging doors?

Yes. Vision panels on doors like the PE-620ALC premium aluminum swinging door provide visibility while remaining impact-resistant and secure.

What accessories help extend the lifespan of brewery swinging doors?

Add-ons such as bumpers, kick plates, and steel frames protect doors from daily wear. These upgrades are recommended for all models, including the PE-710 and PE-8000.

Can swinging doors be locked after hours?

Yes. Lockable hardware can be added to any model, allowing entrances to be secured once the brewery closes.

Can I order custom-sized swinging doors for my brewery?

Yes. All models, including the PE-720 versatile ABS swinging door, can be tailored to fit unique openings, from oversized panels to narrow hallways.

How durable are swinging doors in brewery conditions?

Very durable. The PE-8000 industrial door withstands heavy impacts and wash-down cleaning, while the PE-710 resists constant cart and keg traffic.

Do swinging doors reduce noise and improve guest experience?

Yes. Solid-core models like the PE-620ALC aluminum door soften brewing sounds, and optional windows connect guests to the craft process without safety risks.

Will brewery odors seep into the taproom?

Perimeter seals and insulated models, such as the PE-8000, help contain strong aromas of hops and fermentation, keeping the taproom comfortable.

Are swinging doors good for high-traffic breweries?

Yes. The PE-710 excels in keg and cart corridors, while the PE-720 handles constant taproom-to-brewhouse traffic.

Can brewery swinging doors handle wash-down cleaning?

Yes. The PE-8000 industrial door is USDA-accepted and built to withstand wash-down cleaning in production areas.

Do swinging doors comply with food and beverage standards?

Yes. The PE-8000 meets USDA standards, making it a trusted option for breweries with strict sanitation requirements.

Can swinging doors match my taproom’s design?

Yes. The PE-620ALC aluminum swinging door has a brushed aluminum finish that enhances guest-facing areas with a polished, modern look.

Are swinging doors better than traditional hinged doors for breweries?

For most breweries, yes. Models like the PE-720 versatile swinging door improve traffic flow, reduce collisions, and require less maintenance than hinged doors.

Do swinging doors take up a lot of space?

No. Because they swing both directions and return to center, models like the PE-710 work well in narrow brewery hallways without extra clearance.

How long do brewery swinging doors typically last?

With add-ons like kick plates and bumpers, models such as the PE-720 and PE-8000 can last many years, even under heavy use.

Are installation services available for these doors?

Yes. Most suppliers provide installation support to ensure models like the PE-710 and PE-8000 are fitted correctly for brewery environments.

Can swinging doors be retrofitted into existing brewery openings?

Yes. The PE-720 versatile ABS swinging door can often be sized to fit existing openings without major construction, making it a flexible retrofit option.

Photo Gallery

Bring Efficiency and Style to Your Brewery

Choosing the right swinging doors is more than a design choice, it’s an investment in smoother operations and a polished taproom experience. For microbreweries, these doors keep production moving efficiently while elevating the customer-facing side of the business. Explore the PE-620ALC, PE-710, PE-720, and PE-8000 models to see which fits your space best, and request a Rapid Quote today to upgrade your brewery with a solution that flows as smoothly as your craft beer.

Microbrewery Interior Design