How to Choose the Right Industrial Swinging Door

Industrial swinging doors play a vital role in maintaining smooth, safe, and efficient movement within busy facilities. In this guide, we’ll walk you through the key factors that go into choosing the right door for your space—from traffic type and temperature control to compliance needs—so you can find a solution that fits your operations perfectly.

Why Door Selection Matters in Industrial Environments

In busy industrial settings, your choice of swinging door isn’t just about access—it’s about performance. The right door becomes part of your workflow, while the wrong one creates friction. This section uncovers the hidden costs of poor door selection and why a carefully chosen door is essential to keeping operations running safely and efficiently.

Inefficiency Hurts Your Operations

Every slowdown at a doorway adds up—whether it's from a door that’s hard to push open, lacks visibility, or simply doesn’t match your traffic flow.

Over time, those micro-delays can lead to bottlenecks, lost productivity, and employee frustration. In high-volume environments, even seconds matter.

A mismatched door may seem like a small issue—until it starts impacting everything from throughput to safety compliance.

What Happens When You Choose the Wrong Door?

Poor door selection can lead to:

- Faster wear and tear, resulting in frequent repairs or replacement

- Workflow interruptions, especially in high-traffic or equipment-heavy zones

- Energy loss in climate-sensitive areas like freezers or cleanrooms

- Increased safety risks, including limited visibility and clearance issues

- Regulatory setbacks, particularly in USDA- or FDA-regulated spaces

Types of Industrial Swinging Doors

Not all swinging doors are created equal—and choosing the right model can drastically improve safety, efficiency, and compliance in your facility. Here’s a quick guide to AKON’s most popular industrial swinging doors, each designed for a specific environment and operational need.

Ideal for warehouses, retail backrooms, and light industrial areas, the PE‑1500 is a reliable choice for daily use.

- Lightweight polyethylene panel for ease of use

- V‑Cam hinge system for smooth, long-lasting swing action

- Customizable with vision panels and impact bumpers

- Perfect for foot traffic and cart access

🔗 Best used in general warehouse aisles, employee access points, and breakroom entries.

Designed for environments where temperature control is critical, the PE‑8000 helps minimize energy loss and protect product integrity.

- Dual-pane insulated core for superior thermal separation

- Moisture-resistant, gasketed panel edges

- Spring-loaded hinges for a tight, consistent seal

- Withstands frequent cycles in freezer and cooler zones

🔗 Great for walk-in freezers, cold storage warehouses, and food prep areas.

When sanitation and regulatory compliance are top priorities, the PE‑9000 delivers.

- Smooth, non-porous surfaces approved for food and pharma

- USDA/FDA-compliant construction

- Resistant to mold, mildew, and harsh cleaning agents

- Available with stainless steel hardware and anti-microbial finishes

🔗 Recommended for cleanrooms, food processing plants, and pharmaceutical facilities.

For the toughest environments, the PEX‑9000 is built to take a beating—without sacrificing performance.

- Reinforced polyethylene panel with steel frame core

- Rated for heavy forklift and cart impact

- Optional full-height bumpers and jamb guards

- Extended cycle life in high-traffic areas

🔗 Perfect for loading docks, distribution centers, and manufacturing zones.

How to Match the Right Door to Your Facility Needs

Every facility has its own set of challenges—and your door needs to match them. Choosing the right industrial swinging door starts with understanding your environment. Below are five key factors to consider when narrowing down your options.

Start by identifying what moves through your doors daily. Are you dealing with foot traffic, hand carts, pallet jacks, or forklifts?

- Light traffic = PE-1500 or PE-9000

- Heavy traffic with carts or equipment = PEX-9000

- Look for V-Cam or Easy-Swing hinges that can handle frequent use without binding or failure.

A high-traffic zone needs a door that can swing freely and reset quickly—without slowing your team down.

If your facility includes refrigerated areas, cleanrooms, or any climate-sensitive zone, your door choice plays a big role in thermal retention.

- Cold storage → PE-8000 with insulated core and gasketed edges

- Climate zoning → Vision panels and sealed doors reduce air exchange

- Prevent energy loss and protect temperature-sensitive inventory

The right door helps maintain air separation and reduces HVAC load.

For food, beverage, and pharmaceutical facilities, compliance isn’t optional.

- USDA/FDA-regulated environments → PE-9000 for smooth, non-porous surfaces

- OSHA safety zones → Consider models with clear vision panels and optional warning signage

- Ask if your door is cleanable, anti-microbial, and suitable for wash-downs

Choosing the wrong door in a regulated environment could lead to fines or shutdowns.

Not all door frames are created equal. Consider where the door will be mounted and what kind of clearance is available.

- Mounting to drywall or metal studs may require lighter models like PE-1500

- Concrete block or cold room panels can support heavier-duty options

- Double-check swing clearance to prevent obstruction

Proper installation is just as necessary as proper selection.

If your doors take regular hits from carts or forklifts, choose one that’s built to withstand abuse.

- PEX-9000 includes steel reinforcements and full-height bumpers

- Add jamb guards and kick plates to extend the life of your investment

- Look for doors tested for high-cycle applications

A more durable door upfront prevents repeated downtime and costly replacements.

Common Mistakes When Choosing a Door

Not all swinging doors are created equal—and choosing the right model can drastically improve safety, efficiency, and compliance in your facility. Here’s a quick guide to AKON’s most popular industrial swinging doors, each designed for a specific environment and operational need.

Undersizing the Doorway

Jamb Guards are used to raise the lower door hinge off the floor preventing it from damage caused by pallet jacks and forklifts. Available in full stainless-steel for special applications.

Overlooking Traffic Frequency

Light-duty doors won’t hold up in high-volume zones. Choose heavy-duty hinges like V-Cam or Easy-Swing for frequent daily use.

Using the Wrong Material

A door suited for dry storage may not perform in cold or sanitary areas. Match door materials (insulated, gasketed, smooth) to zone requirements.

Not Planning for Mounting

Both C-channel and Tubular frames options are available to provide strength and integrity to your door installation. All frames are 3-piece construction and pre-drilled for hinges (Making door installation easier).

Frequently Asked Questions

Frequently Asked Questions About Swinging Doors

What’s the difference between a traffic door and a swinging door?

The terms are often used interchangeably. Both refer to doors that swing in both directions and automatically return to center. They’re designed for high-traffic areas and require no hands to operate—ideal for fast-paced environments.

How do I know which door is best for my facility?

It depends on your traffic type, volume, and environment. Light-duty use? Consider the PE-1500. Cold storage? Go for the PE-8000. USDA-regulated? The PE-9000 is compliant. Heavy traffic zones? You’ll want the PEX-9000 with reinforced durability.

Do these doors require special framing or installation?

Most swinging doors can be mounted to standard wall types, but the surface matters. Lightweight doors work best on drywall or studs. Heavier doors may need concrete or metal framing. Pre-drilled steel frames are available for easier installation.

Can these doors be used in cold storage or wash-down areas?

Yes, but only certain models. The PE-8000 is designed with insulation and gasketed edges for temperature control. The PE-9000 features smooth, non-porous surfaces for easy sanitation—perfect for USDA or FDA environments.

What’s the lifespan of a commercial swinging door?

With the right model and proper installation, these doors can last 10+ years—even in high-traffic facilities. Look for options with rugged hinges and reinforced cores to extend service life and minimize downtime.

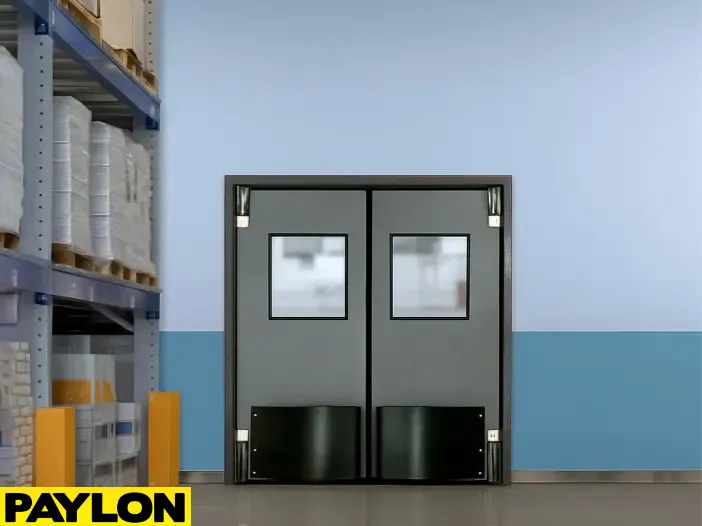

Photo Gallery

Conclusion: The Right Door Makes All the Difference

Choosing the right industrial swinging door isn’t just about aesthetics—it’s about efficiency, safety, and long-term performance. Whether you’re managing light foot traffic or heavy equipment zones, the right door can streamline operations, reduce maintenance, and support regulatory compliance.

From traffic volume and climate needs to mounting conditions and materials, every detail matters. Avoiding the common mistakes and asking the right questions will save you time, money, and future headaches.

Ready to choose a door that fits your facility perfectly? Let our team help you find the right swinging door solution. Reach out today for expert guidance and a quote tailored to your exact needs.