Warehouse & Distribution Swinging Doors

Warehouses and distribution centers depend on smooth, safe movement to keep operations running efficiently. Swinging doors help by reducing slowdowns, improving visibility, and allowing staff, carts, and equipment to pass through busy areas without interruption. This article explains how swinging doors enhance workflow and safety, compares four door models suited for different traffic levels, highlights useful add-ons, and helps you choose the best solution for your warehouse or distribution center’s needs.

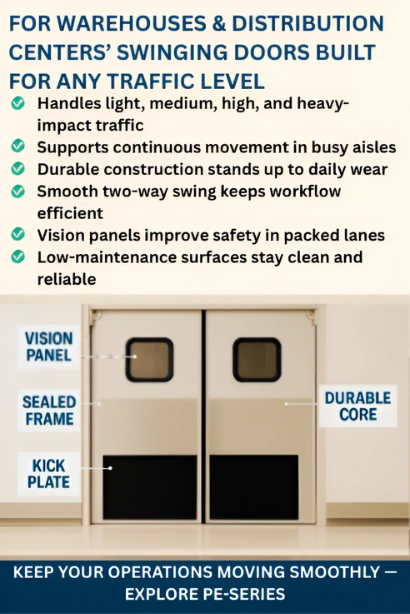

Engineered for Industrial Traffic Demands

Swinging doors help both warehouses and distribution centers stay productive and organized. Whether you're managing light staff movement or handling high-volume forklift traffic, the right door ensures smoother workflow and improved safety. With durable construction and customizable safety features, these doors meet the needs of any facility type. This guide will help you choose the best model for your warehouse or distribution center, considering traffic levels, add-ons, and essential features.

How Swinging Doors Improve Workflow and Safety

In fast-paced environments like warehouses and distribution centers, efficient movement is key to maintaining productivity. Swinging doors help by improving how people, carts, and equipment move through busy areas without slowing down. Whether it’s a light staff movement or high-volume traffic, these doors create a more predictable flow and enhance safety. Below are the main ways they contribute to a smoother, safer operation.

Smoother Movement Across Busy Facility Zones

Steady Movement Through Busy Areas

Swinging doors help staff, carts, and pallet jacks maintain a steady pace in high-activity zones. Their two-way swing lets people move freely without stopping or adjusting their path, which helps prevent slowdowns during tasks like restocking or order fulfillment.

Better Flow Between Work Areas

By keeping movement continuous, these doors help reduce aisle congestion and support smoother transitions between different parts of the facility. This consistent flow keeps teams on schedule and allows warehouses and distribution centers to handle shifting activity levels more efficiently.

Improved Visibility and Safer Traffic Flow

Clear Visibility in High Traffic Areas

Swinging doors help reduce collisions by giving workers a better view of approaching traffic. Vision panels make it easier to see what is on the other side, which helps staff move through crowded pathways with more confidence and awareness.

Safer Separation of Foot and Equipment Paths

The natural swing of the door guides movement into smoother, more predictable lanes. This helps separate pedestrian and equipment traffic, lowering risks for workers operating in busy zones and supporting a safer flow during peak hours.

Best Swinging Door Models for Warehouses and Distribution Centers

Every warehouse and distribution center has unique movement patterns and activity levels. Choosing the right swinging door helps match those demands, ensuring smooth operations and safe environments. The models below are designed to meet different traffic conditions, offering clear options that fit light use, steady workflows, high-volume activity, and heavy equipment lanes.

The PEX-9000 is a great choice for areas that see moderate daily movement without heavy equipment traffic. It offers an easy-to-use design that works well in smaller sections of a warehouse or distribution center.

• Easy to open and operate

• Works well in quieter warehouse sections

• Supports moderate staff and cart movement

PE-1500 for General Warehouse Zones

The PE-1500 delivers a balanced mix of strength and smooth function for steady daily activity. It works especially well in spaces where staff move often and need a door they can rely on.

• Durable design for steady daily use

• Smooth swing for consistent movement

• Good match for active warehouse teams

The PE-8000 is designed for busy distribution lanes that have a constant flow of movement. Its reinforced construction helps it stand up to long hours and frequent use.

• Reinforced for demanding environments

• Customizable to fit busy lanes

• Handles continuous cart and staff movement

The PE-9000 is built for the toughest areas where forklifts, pallet jacks, and equipment move throughout the day. Its insulated panel and durable build help protect it from repeated impact.

• Withstands heavy equipment traffic

• Durable insulated panel for protection

• Suitable for high-impact warehouse lanes

Find the Right Model for Your Warehouse

After knowing the features and benefits of each model, it's helpful to see a side-by-side comparison. The table below gives you a quick way to compare traffic levels, ideal locations, and core strengths so you can confidently choose the door that best fits your warehouse or distribution center.

| Model | Best For | Traffic Level | Key Strengths |

|---|---|---|---|

| PEX-9000 | Light warehouse zones and backrooms | Light to Medium | Lightweight, easy to use, low maintenance |

| PE-1500 | General warehouse floors | Medium | Balanced durability, smooth swing, insulated panel |

| PE-8000 | Busy distribution lanes | High | Reinforced build, customizable sizes, continuous use ready |

| PE-9000 | Forklift and equipment lanes | Very High | Thick panel, full height bumpers, built for heavy impact |

This comparison gives you a clearer look at how each model performs in different parts of your warehouse or distribution center. Understanding the traffic level and strengths of each model will make it easier to select the best door for your unique needs, ensuring both smoother workflow and better safety.

Helpful Add-Ons and Features

Swinging doors become even more effective when paired with the right upgrades. These add-ons help improve durability, safety, and long-term performance in both warehouses and distribution centers. Below is a quick look at the features customers often choose to enhance their door systems.

| Feature | Why It Matters in Warehouses & Distribution Centers |

|---|---|

| Impact Bumpers | Helps protect the door from frequent impacts caused by carts and equipment, extending the life of the door and minimizing maintenance. |

| Kick Plates | Prevents wear and tear at the bottom of the door, especially in areas with high cart or equipment traffic. |

| Jamb Guards | Protects the door frame and hinges from damage caused by heavy-duty traffic, reducing repairs and ensuring long-term performance. |

| Vision Panels | Improves visibility in high-traffic areas, helping staff spot incoming traffic or obstacles to reduce the risk of collisions. |

| Stainless or Painted Frames | Frames made from durable materials like stainless steel or painted finishes protect the door against moisture, rust, and harsh chemicals, ensuring longevity. |

These add-ons help you customize your swinging door system based on how your facility moves, the type of equipment you use, and the level of traffic your team manages each day. Selecting the right combination ensures your doors stay reliable, safe, and better suited to your workflow.

Frequently Asked Questions

FAQs for Warehouses and Distribution Centers

What swinging door is best for heavy distribution traffic?

The PE-8000 swinging door is ideal for distribution centers with nonstop activity. Its reinforced build handles continuous movement without slowing staff or equipment.

Which swinging door works best for forklift lanes in a warehouse?

The PE-9000 heavy-impact swinging door is made for forklift paths. Its thicker panel and strong frame hold up well in areas with frequent equipment movement.

Can the PE-9000 door handle repeated forklift passes throughout the day?

Yes. The PE-9000 is engineered for constant equipment traffic and maintains reliable performance even in high-impact zones.

Do swinging doors help reduce accidents in fast-paced facilities?

They can. Vision panels and smooth, predictable swing patterns help reduce blind spots and make movement safer in busy loading areas and picking aisles.

How long does a PE-Series industrial swinging door usually last?

Most PE-Series doors last for many years with routine use. Lifespan depends on your traffic level, environment, and maintenance schedule.

Are PE-Series swinging doors easy to maintain?

Yes. These doors are designed for simple upkeep. Regular cleaning and an occasional hardware check are usually all that is needed.

Can I add vision panels to any PE-Series swinging door?

Yes. Vision panels are available for all models and help staff see oncoming traffic before pushing through.

Do impact bumpers fit on every model?

They do. Impact bumpers can be added to any PEX-9000, PE-1500, PE-8000, or PE-9000 door to help protect against carts and equipment.

Are PE-Series swinging doors good for smaller warehouses too?

Yes. The PEX-9000 swinging door is a great match for light to medium activity zones commonly found in smaller facilities.

Can these doors improve traffic flow in tight warehouse aisles?

Yes. Their two-way swing and smooth motion help teams move quickly through narrow or busy areas without slowing down.

Are PE-Series doors noisy when opening and closing?

No. They are designed for quiet operation, which helps maintain a calm environment in both warehouses and distribution centers.

Can these doors be made to fit wider or taller openings?

Yes. Models like the PE-8000 and PE-9000 can be built in custom sizes to match your doorway and workflow requirements.

Do swinging doors help separate pedestrian and equipment paths?

Yes. Their natural guiding movement and visibility features help create smoother traffic patterns between staff and forklifts.

Is upgrading to stainless steel frames worth it?

If your facility deals with moisture, cleaning chemicals, or temperature shifts, stainless frames can improve durability and reduce corrosion risks.

Do swinging doors help with dust or temperature control?

They help reduce airflow between zones, which can limit dust transfer and support temperature stability in storage or packing areas.

Are PE-Series doors suitable for cooler storage zones or chilled areas?

Yes. The PE-9000 and PE-1500 work well near cooler entrances or other temperature-controlled sections of a warehouse.

Can kick plates be added to any door model?

Yes. Kick plates are available for all PE-Series models and help protect the lower panel from frequent use.

How do I choose the right swinging door for my facility?

Think about your traffic level, equipment use, aisle layout, and safety needs. The comparison table in this guide can help you decide which PE-Series model fits best.

Are PE-Series swinging doors easy for staff to push through?

Yes. These doors are built for easy, low-effort operation so staff, carts, and pallet jacks can move without interruption.

Can these doors handle daily use in a busy distribution center?

Absolutely. Models like the PE-8000 and PE-9000 are reinforced for long hours, constant traffic, and demanding environments.

Photo Gallery

Choosing Your Next Step

Selecting a swinging door for a warehouse or distribution center is easier when you understand how each model supports different parts of your facility. The PE-Series gives you reliable options built for the demands of everyday operations, whether you manage lighter activity or equipment-heavy areas. Take a moment to review what your space needs, then explore the PE-Series lineup to find a door that delivers the long-term performance your team can depend on.

Smart Door Solutions for Compact Workspaces