Industrial Factory Swinging Doors

In busy factory environments where equipment moves constantly and safety is critical, the right door system makes all the difference. Industrial factory doors are designed for nonstop use, offering strength, organization, and energy efficiency. This guide covers common factory challenges, top door models, key features, and expert tips to help you choose the right solution for your facility.

Engineered for Heavy-Duty Performance

Industrial factory doors are the backbone of smooth, efficient operations. Built for nonstop movement and heavy use, they combine strength, safety, and performance in one design. From forklift zones to food-grade areas, every model is engineered for long-lasting reliability. Choose from durable, insulated, and reinforced options that fit your facility’s unique needs. Keep your workflow seamless and your team safe with industrial swinging doors designed for real-world factory demands.

Common Factory Challenges These Doors Solve

In busy factory environments, constant movement and temperature shifts can quickly expose the weaknesses of standard doors. What seems like a small issue often leads to lost time, energy waste, and added maintenance. Understanding these challenges helps explain why upgrading to industrial swinging doors can make such a difference in everyday operations.

Why Standard Doors Fall Short in Industrial Settings

When Standard Doors Slow Down Operations

Traditional factory doors often struggle to keep up with nonstop activity. After repeated impact from carts and forklifts, they begin to bend, jam, or swing unevenly.

This slows down workers moving between production zones and causes bottlenecks that interrupt daily operations. What starts as a small inconvenience quickly turns into wasted time and reduced productivity.

How Door Damage Affects Efficiency

As standard doors wear down, their seals loosen and panels warp, allowing conditioned air to escape. This forces HVAC systems to work harder, raising energy costs and creating uncomfortable work conditions.

Damaged doors also require frequent repairs, adding to maintenance expenses. Over time, these issues combine to affect workflow, safety, and overall operating efficiency.

How Industrial Swinging Doors Improve Factory Performance

How Industrial Swinging Doors Solve These Issues

Industrial swinging doors are built to meet the demands of nonstop factory activity. Their reinforced cores and heavy-duty panels absorb repeated impacts from carts and forklifts without bending or cracking.

Each door stays properly aligned, allowing smooth movement between work areas and minimizing downtime caused by maintenance or repairs.

Why They Perform Better in Busy Environments

Tight perimeter seals on industrial swinging doors help maintain stable temperatures, preventing energy loss in climate-controlled zones. The double-acting hinges allow quick, hands-free access that improves workflow and safety.

Because they require minimal upkeep and withstand years of heavy use, these doors deliver consistent performance and long-term reliability in even the most demanding industrial settings.

Recommended Door Models for Factory Applications

Every factory operates differently, with its own level of traffic, workflow, and safety needs. Choosing the right door means matching its strength and design to your environment. Below are four industrial swinging door models designed to help factories improve movement, energy efficiency, and durability in everyday operations.

Ideal for production zones with steady but moderate activity, the PE-1500 balances durability and practicality. Its lightweight build makes it easy to operate while maintaining consistent performance in daily use.

• 1.5-inch ABS plastic panels with insulated foam core for energy control

• Handles repeated cart and foot traffic without bending or jamming

• Smooth two-way access that improves workflow between work areas

• Lightweight design reduces strain on hinges for longer life

PEX-9000 – Designed for Temperature-Controlled or Sanitary Zones

The PEX-9000 is perfect for food production, clean packaging, and pharmaceutical facilities. Its insulated structure maintains temperature consistency while preventing cross-contamination in sensitive areas.

• Moisture-resistant composite core for easy sanitation

• Sealed design helps maintain cold or clean environments

• Smooth swing action allows hands-free entry and exit

• Meets hygiene and food safety standards for cleanroom applications

For manufacturing areas with forklifts, pallets, or large machinery, the PE-8000 provides lasting strength and stability. It’s designed to withstand continuous impact while keeping operations running smoothly.

• Reinforced composite panels handle heavy equipment contact

• Heavy-duty hinges keep alignment steady over years of use

• Impact-resistant surface reduces repair and replacement costs

• Ideal for warehouses and production floors with constant movement

When uptime and safety are critical, the PE-9000 delivers unmatched performance. Engineered for nonstop factory use, it combines strength, alignment, and protection for the most demanding applications.

• Steel-reinforced core with full-height bumpers for maximum durability

• Handles constant forklift and cart traffic without warping

• Tight seals minimize air loss and improve temperature efficiency

• Low-maintenance design keeps high-traffic zones running efficiently

Industrial Factory Door Comparison Table

Now that you’ve explored the key features of each model, the table below provides a quick visual comparison to help you identify which door best fits your facility’s needs. Whether your factory handles light foot traffic or nonstop forklift operations, this guide makes it easy to find the right balance between performance, durability, and efficiency.

| Model | Best For | Core Material & Build | Traffic Type | Key Benefits |

|---|---|---|---|---|

| PE-1500 | Medium-traffic areas, staff corridors | 1.5″ ABS plastic with urethane foam core | Foot + cart traffic | Lightweight, energy-efficient, and easy to maintain |

| PEX-9000 | Cold storage or sanitary areas | Insulated PVC/composite core | Foot + light equipment | Excellent temperature control and simple to clean |

| PE-8000 | Heavy-duty industrial access zones | Reinforced composite door with heavy-duty hinges | Forklift + cart traffic | Highly impact-resistant and built for long-term use |

| PE-9000 | Forklift lanes and nonstop production | Steel-reinforced core with full-height bumpers | Forklift + motorized vehicles | Maximum durability with smoother, safer workflow |

Each model offers unique advantages designed to match specific industrial needs. The PE-1500 supports daily efficiency in moderate-use zones, while the PEX-9000 excels in cold or clean environments. For heavier equipment movement, the PE-8000 delivers unmatched durability, and the PE-9000 stands out as the go-to solution for continuous, high-impact operations.

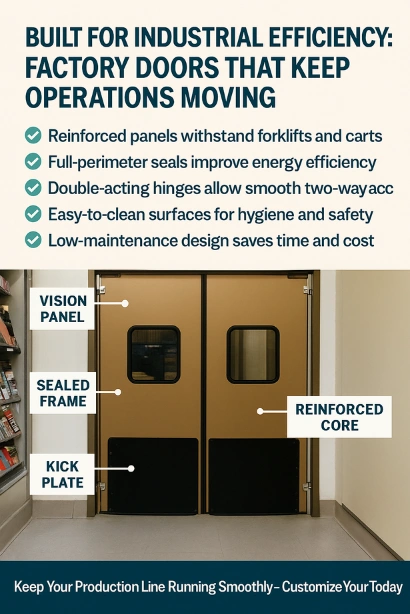

Key Features and Benefits of Industrial Factory Doors

Every industrial factory door shares the same durable, high-performance design that helps factories operate safely and efficiently. These features work together to minimize downtime, reduce maintenance, and maintain control in even the busiest production environments.

| Feature | Why It Matters in Industrial Facilities |

|---|---|

| ✔ Double-acting hinges for hands-free, two-way access | Speeds movement between zones and reduces bottlenecks in busy aisles, helping teams keep production flow steady and safe. |

| ✔ Impact-resistant panels and reinforced construction | Absorbs repeated contact from carts and forklifts without warping, cutting repair needs and extending door service life. |

| ✔ Tight perimeter seals for temperature and air control | Limits air exchange and dust transfer to keep climate-controlled areas stable and reduce energy load on HVAC systems. |

| ✔ Vision panels for safer visibility in high-traffic zones | Improves line-of-sight through the door to help prevent collisions in fast-paced corridors and equipment paths. |

| ✔ Optional add-ons: kick plates, full-height bumpers, window panels | Tailors protection and visibility to the environment, boosting durability in impact areas and keeping doors looking and working new. |

| ✔ Built for long-term efficiency | Reduces maintenance demands and supports cleaner, organized workflows, improving overall productivity and total cost of ownership. |

Industrial factory doors are built for more than durability, they’re designed to enhance safety, airflow, and energy control. Each feature works together to keep operations smooth, efficient, and low maintenance, helping factories stay productive year after year.

Frequently Asked Questions

FAQs – Industrial Factory Doors

Industrial factory doors like the PE-1500, PEX-9000, PE-8000, and PE-9000 are built from durable ABS plastic, insulated PVC, or steel-reinforced cores. These materials are engineered for long-term impact resistance and reliable performance in busy factory environments. Yes. Both the PE-8000 and PE-9000 industrial swinging doors are designed for high-impact traffic, including forklifts and pallet jacks. Their reinforced cores and heavy-duty hinges absorb repeated collisions without bending or misaligning. Absolutely. Both the PE-1500 and PEX-9000 include insulated cores and perimeter seals that minimize air leakage, helping factories maintain temperature zones and lower energy costs. With proper maintenance, high-quality models like the PE-8000 and PE-9000 can last over a decade. Their impact-resistant construction is made to handle thousands of openings per day without losing alignment. Yes. All models can be customized by size, panel color, vision window style, and hardware. You can choose options that fit your factory layout and match your facility’s workflow. The PEX-9000 industrial factory door uses a moisture-resistant composite core and sealed edges to maintain hygiene and temperature control, perfect for food, pharmaceutical, or cleanroom environments. Yes. Models with built-in vision panels and double-acting hinges, like the PE-1500 and PE-9000, improve visibility and allow hands-free operation to reduce accidents in busy corridors. Industrial swinging doors like the PEX-9000 and PE-1500 use tight perimeter seals and insulated cores that maintain temperature consistency, cutting down on HVAC strain and energy waste. Yes. The PE-1500 is built for moderate-traffic areas where carts, bins, and staff pass constantly. Its lightweight design keeps movement efficient without sacrificing durability. Yes. The PE-8000 features smooth, non-porous surfaces that can be wiped clean quickly, making it ideal for manufacturing areas where cleanliness and maintenance speed matter. Yes. The insulated cores in models like the PE-1500 and PE-8000 naturally dampen sound between production areas, helping maintain a quieter, more focused workspace. In most cases, yes. Models like the PE-1500 and PEX-9000 can be fitted into existing frames with minimal modification, allowing for quick upgrades with little downtime. Double-acting hinges, found in all PE series doors, let the door swing in both directions for hands-free access. This keeps workflow smooth and prevents delays in high-traffic zones. Yes. Models such as the PEX-9000 and PE-8000 use rust-resistant hardware suitable for humid or washdown environments, ensuring long-term reliability. All PE and PC series doors meet industry standards for safety, durability, and hygiene. Many models are also designed to comply with USDA and FDA requirements where applicable. While primarily made for indoor use, certain models like the PE-9000 can be adapted for covered loading docks or sheltered exterior openings with proper sealing. Yes. The PE-8000 and PE-9000 are perfect for manufacturing zones that require strength, impact resistance, and corrosion-proof hardware under demanding conditions. Basic cleaning and periodic hinge checks are usually enough. Their durable design minimizes repair frequency, helping you avoid costly downtime and part replacements. Yes. All PE and PC models include a warranty covering materials and craftsmanship, giving you long-term confidence in their performance. You can request a quote directly from us to find the right model, whether you need a PE-1500 for light use or a PE-9000 for nonstop forklift traffic. Our team can help match the best option for your factory’s daily demands.What are industrial factory doors made of?

Can PE-8000 or PE-9000 doors handle forklifts and pallet jacks?

Are PE-1500 and PEX-9000-1000 industrial doors energy-efficient?

How long do industrial swinging doors last in heavy-use areas?

Can these doors be customized for different factory layouts?

What makes the PEX-9000 ideal for sanitary or cold-storage zones?

Do industrial factory doors improve workplace safety?

How do these doors help reduce energy loss?

Can PE-1500 doors handle frequent cart or foot traffic?

Are PE-8000 industrial swinging doors easy to clean?

Do these doors help with noise control?

Can I retrofit industrial swinging doors into existing openings?

How do double-acting hinges help factory efficiency?

Are these doors resistant to rust and corrosion?

Do industrial swinging doors comply with safety standards?

Can these doors be installed outdoors or in semi-exposed areas?

Are industrial factory doors suitable for chemical or manufacturing plants?

What maintenance do industrial factory doors need?

Do these doors come with a manufacturer warranty?

Where can I buy industrial factory doors for my facility?

Photo Gallery

Upgrade Your Facility for Maximum Efficiency

Choosing the right industrial factory doors is one of the easiest ways to boost your facility’s efficiency, safety, and workflow. Each model, from the lightweight PE-1500 to the heavy-duty PE-9000, is designed for nonstop use, helping improve movement, protect equipment, and reduce energy loss. With durable materials, reinforced cores, and precision engineering, these doors deliver long-term reliability and cost savings. Explore our full line of Industrial Factory Doors and request a free quote today to find the perfect fit for your facility.

Efficient Factory Design for Production Flow