Traffic Swinging Doors

Looking for the right traffic swinging doors for butcher shops or meat processing areas? This guide covers why specialized doors matter, compares four top models, breaks down key features, shares tips on installation and upkeep, and answers common questions so you can confidently choose the best fit for your facility.

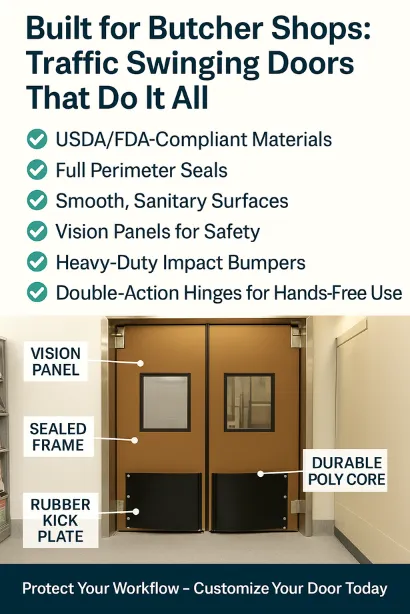

Designed for USDA Standards

When safety, sanitation, and nonstop workflow matter most, every detail counts. This infographic highlights the essential features that make our traffic swinging doors ideal for butcher shops and meat processing facilities. From USDA-compliant materials to impact-resistant construction, these doors are engineered to keep your team moving and your facility inspection-ready. Explore your options, compare models, and customize your setup with help from the experts at Traffic Swinging Doors.

Key Benefits That Matter to Butcher Shops and Processing Facilities

When operations are fast-paced and precision matters, the right door setup can make a big difference. Here’s how our traffic swinging doors help keep your workflow smooth and your facility in compliance:

🔒 Sanitation & Temperature Control

Keep It Sanitary

Designed for daily use in food-handling environments, these smooth, non-porous surfaces are easy to sanitize and resist contamination, ideal for meat rooms and prep areas.

Control Cold Zones

Insulated cores and full perimeter seals help minimize air exchange, keeping your coolers and freezer sections consistently temperature-controlled.

🚛 Built for Tough, High-Traffic Use

Handle Heavy Use

Whether it’s carts, pallet jacks, or nonstop foot traffic, these doors are engineered to absorb repeated impact without cracking, bending, or slowing your team down.

Move Efficiently

Double-action swing functionality allows the door to open in either direction with minimal effort, keeping staff moving smoothly even when hands are full.

Which Traffic Door Model Is Best for Your Facility?

Not all meat processing areas face the same demands. Some zones see light foot traffic, while others require rugged insulation and impact resistance. Below is a detailed comparison of our four traffic swinging door models, each one suited to a specific type of facility, workflow, and durability need.

The PE-1500 is perfect for butcher shops and prep rooms that don’t require heavy-duty durability. Its lightweight design makes it a cost-effective and sanitary option for spaces where carts and forklifts aren’t in use. Simple, clean, and USDA-compliant, it’s built for ease and speed.

- Best for small butcher counters, back-of-house prep areas, and employee-only zones

- Polyethylene construction resists moisture and daily washdown

- V-cam hinges provide smooth, low-resistance swing in both directions

- Budget-conscious option that still meets hygiene and compliance standards

Need something stronger than a basic prep door, but not quite as industrial as a freezer-grade model? The PE-8000 is that sweet spot. It’s designed to handle regular traffic, including wheeled carts, while maintaining a lightweight swing and clean surface.

- Great for processing zones, storage access, and packaging stations

- Slightly thicker core provides better impact resistance than the PE‑1500

- Compatible with stainless-steel options for USDA-inspected washdown areas

- Vision panels enhance safety in high-movement zones without compromising privacy

If your team is pushing pallet jacks, moving product constantly, or working in high-speed areas, the PE-9000 is your door. Designed with a rigid ABS surface and internal frame, it can take a beating and keep moving without cracking, warping, or slowing down your workflow.

- Best for production floors, cutting rooms, and loading areas with high traffic

- Heavy-duty build withstands forklifts, jacks, and repeated impact

- Full perimeter seal options help with airflow control and cleanliness

- A long-term, high-performance solution for demanding meat environments

4. PEX-9000 – Cold-Room Ready for Freezers and Extreme Environments

Cold storage zones and blast chillers demand more than just a sturdy door, they need insulation, resistance to temperature shock, and long-term durability. The PEX-9000 delivers on all fronts, keeping your walk-ins sealed, safe, and efficient.

- Insulated core prevents cold air loss, reducing energy consumption

- Rugged outer shell won’t crack in subzero temperatures or humid conditions

- Designed for areas where cleanliness and temperature control are mission-critical

- Ideal for freezer sections, cold packaging lines, or meat holding rooms

Built for the Demands of Meat Facilities: Features You Can Count On

When your operation runs full tilt and downtime isn't an option, your traffic doors need more than just good looks, they need performance you can trust. That’s where industrial-grade features make a difference.

Designed specifically for meat rooms, butcher shops, and USDA-inspected zones, these features ensure your doors hold up to daily punishment while supporting your food safety and efficiency goals.

Below is a quick breakdown of the features that matter most in meat processing environments, and how each one solves a real-world problem:

| Feature | Why It Matters in Meat Facilities |

|---|---|

| ✅Full-Perimeter Seals for Hygiene and Temperature Control | Helps maintain clean, climate-controlled environments by minimizing air exchange and keeping out contaminants — ideal for cold rooms and prep zones. |

| ✅Tear-Drop Bumpers and Kick Plates | Protects the door surface from frequent impact by carts or boots, reducing long-term damage and extending service life. |

| ✅Rust-Resistant Hardware for Washdown Zones | Built for sanitation routines, stainless components resist corrosion from frequent high-pressure cleaning and moisture exposure. |

| ✅Clear Vision Panels to Reduce Collisions | Enhances safety in busy corridors by providing visibility through the door — especially helpful in high-traffic, fast-paced meat processing areas. |

| ✅Durable Foam or ABS Cores That Hold Up Under Stress | These industrial-grade cores are engineered not just for insulation, but for durability under constant pressure — making them ideal for facilities where doors take repeated impact and still need to perform. |

When your staff, workflow, and safety standards depend on reliable performance, these core features aren’t optional—they’re essential. With the right door design, your facility stays compliant, protected, and ready to handle the demands of every shift.

Installation, Maintenance, and Compliance Made Simple

Making the right upgrade shouldn't be complicated, and with these traffic doors, it's not. Whether you're retrofitting a butcher shop or outfitting a meat processing zone, here's how these doors check all the boxes with minimal hassle:

| Step | What to Expect | Why It Matters |

|---|---|---|

| 1. Easy Installation | Mounts directly to existing walls or with optional stainless-steel frames. | No need for major construction—fast setup even in retrofit situations. |

| 2. Smooth Cleaning | Non-porous, sealed surfaces withstand regular washdowns. | Keeps sanitation simple and fast—ideal for daily cleaning routines. |

| 3. Meets USDA & FDA Standards | Built with fully compliant materials and cleanable surfaces. | Ensures your facility passes inspections with confidence. |

| 4. Built to Last | Durable core, reinforced hardware, and replaceable bumpers. | Reduces interruptions and helps your doors last longer under daily use. |

Whether you’re working in a cold room, prep area, or main floor, these traffic doors simplify your setup without cutting corners on safety or durability. It’s real-world performance, made easy.

Frequently Asked Questions

FAQs: What Butcher Shops Usually Ask Before Ordering

Can I use these doors in walk-in coolers or freezers?

Yes. The PEX-9000 model is insulated and built to perform in cold environments, making it ideal for walk-in freezers and refrigerated storage areas.

What’s the difference between the PE-1500 and PE-9000?

The PE-1500 is a lightweight, economical door for light traffic. The PE-9000 is built for constant impact and heavy-duty use with pallet jacks and carts.

Are these doors USDA-approved?

Yes. All our traffic swinging doors are made with USDA- and FDA-compliant materials, suitable for use in regulated meat processing areas.

Do your doors work with pallet jacks and carts?

Yes. Models like the PE-8000, PE-9000, and PEX-9000 are built to handle repeated impact from carts and pallet jacks without damage.

Can these doors be cleaned with high-pressure sprayers?

Yes. The surfaces are sealed and water-resistant. Stainless-steel frame options are also available for areas with regular washdowns.

Do you offer custom sizing?

We do. If you have unique wall openings or specific layout requirements, we can custom-fit your doors to meet your exact specs.

How long does installation take?

Installation usually takes just a few hours when using a surface mount or stainless-steel frame kit. Most setups require minimal tools.

Can I install these myself or do I need a contractor?

Many customers install these themselves with the provided instructions. However, a contractor may be helpful for large jobs or wall adjustments.

Do these doors swing both ways?

Yes. All models are designed with double-action hinges, allowing the door to swing open in either direction for seamless traffic flow.

Do you provide quotes for multi-door orders?

Yes. We offer detailed quotes for large facilities and multi-door setups. Just send us your specs and we’ll put together a tailored proposal.

Photo Gallery

Conclusion: Get the Right Door for a Safer, Smoother Operation

The right traffic swinging door does more than open and close—it helps your butcher shop or meat facility run cleaner, faster, and safer. With models tailored to different zones and USDA-compliant materials throughout, you can count on reliable performance shift after shift.

Not sure which model fits your setup best? Our team is here to help. Request a custom quote or reach out for expert guidance on selecting the perfect traffic door for your needs.