Industrial Swinging Doors

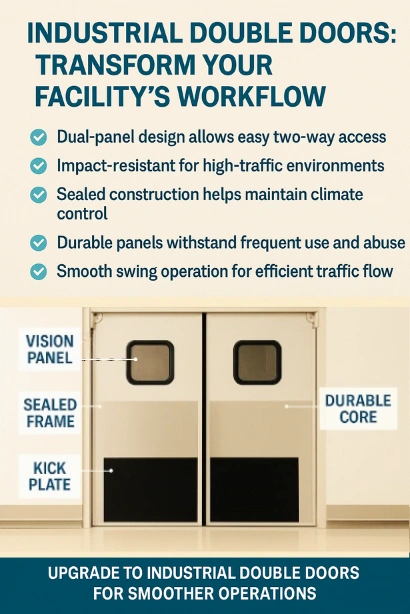

In high-traffic facilities, constant movement can cause delays and safety concerns. Industrial double doors solve this with two durable panels that swing both ways for smooth, reliable access. This guide explores their key benefits, featured models, buying considerations, and real-world uses to help you choose the right fit for your facility.

Built to Meet Industrial Safety & Durability Standards

Industrial double doors are essential for smooth, safe, and organized operations. Built for constant traffic, our PE-Series doors feature impact-resistant cores, sealed frames, and clear vision panels that keep teams moving without interruptions. Ideal for warehouses, production floors, and loading docks, these doors deliver lasting strength and efficiency in every swing, helping your facility run better, faster, and safer.

Why Industrial Double Doors Matter in Busy Facilities

After knowing how industrial double doors enhance workflow and safety, it’s easy to understand why they’re a vital part of today’s fast-paced environments. Each door is built to handle the nonstop pace of warehouses, production lines, and loading docks. Beyond improving movement, they help reduce maintenance costs, maintain cleanliness, and create safer, more efficient workspaces.

Built for Durability and Long-Term Performance

Reduce Downtime and Save on Repairs

Frequent door repairs can slow production and cut into valuable work hours. Industrial double doors are built to withstand daily use, minimizing these interruptions.

Their reinforced panels handle constant movement and impact from carts or equipment without damage. This durability lowers maintenance needs, helping facilities stay productive and focused on what matters most.

Built for Heavy Use and Lasting Reliability

When equipment and staff are constantly on the move, your doors should be just as dependable. Industrial double doors feature sturdy cores and strong hinge systems that keep them operating smoothly under pressure.

Designed for long-term performance, they deliver consistent strength and reliability, ensuring your workflow never stops due to door-related issues.

Maintain Clean, Safe, and Controlled Workspaces

Maintain Clean, Efficient Workspaces

Clean, organized spaces support safer and more productive operations. Industrial double doors help achieve this by creating sealed zones that separate work areas and reduce cross-contamination.

The tight frame fit prevents dust and debris from entering while supporting a smoother, quieter workflow that keeps your facility professional and well-maintained.

Enhance Safety and Climate Control

Stable temperatures and visibility are key to a controlled environment. Industrial double doors are designed to limit airflow between zones and prevent energy loss.

Clear vision panels allow staff to see movement on both sides, reducing collision risks. These combined features make your facility cleaner, safer, and more energy-efficient every day.

Featured Industrial Double Door Models

Now that you know how industrial double doors enhance workflow, cleanliness, and safety, it’s time to find the model that best fits your facility. Each model in the PE-Series is engineered for specific work conditions, from temperature-sensitive environments to high-impact industrial zones, helping you choose the right door for lasting performance and reliability.

The PE-1500 is built for spaces that require sanitation and climate consistency. Its tight sealing design prevents temperature loss and contamination in sensitive areas.

• Full-perimeter seal protects against dust, debris, and moisture

• Reinforced frame and optional bumpers absorb frequent impacts

• Smooth, self-closing panels improve airflow control

• Ideal for cold storage, food processing, and sanitary workspaces

PE-8000: Wide Access for Forklifts and Equipment

The PE-8000 supports constant movement in high-traffic areas where heavy equipment operates daily. Its wide opening and strong hinge system make it perfect for fast-paced facilities.

• Extra-wide panels for forklifts, pallet jacks, and carts

• Rigid core structure resists wear and maintains balance

• Two-way swing allows smooth access during peak activity

• Best for warehouses, production floors, and shipping areas

For demanding spaces with nonstop activity, the PE-9000 offers maximum strength and endurance. It’s designed to handle frequent impacts while keeping operations efficient.

• Heavy-gauge panels and reinforced hardware for extreme durability

• Built for high-cycle, heavy-impact industrial conditions

• Reliable hinge system ensures long-term smooth operation

• Perfect for manufacturing plants and distribution centers

The PEX-9000 combines smooth function with durability, making it ideal for facilities that need dependable performance in moderate-traffic areas. It delivers consistent quality without added bulk or maintenance demands.

• Lightweight yet durable construction for daily use

• Smooth, balanced swing enhances workflow efficiency

• Available in multiple finishes to match any workspace design

• Best for light industrial settings, prep areas, and maintenance zones

Industrial Double Door Models

To make choosing easier, this quick comparison highlights the core strengths of each model side by side. Every PE-Series door is engineered for a specific workload and environment, balancing durability, performance, and accessibility. Use this chart to find which model aligns best with your facility’s traffic level and daily operations.

| Model | Best For | Key Features | Traffic Level | Ideal Environments |

|---|---|---|---|---|

| PE-1500 | Heavy-duty impact protection and temperature control | Full perimeter door seal, reinforced frame, optional bumpers and impact plates | High | Cold storage, food processing, wash-down areas |

| PE-8000 | Wide openings and frequent equipment passage | Rigid core panels, durable hinges, smooth two-way swing | High | Warehouses, shipping areas, production lines |

| PE-9000 | Maximum durability in extreme conditions | Heavy-gauge panels, reinforced hardware, high-cycle design | Very High | Industrial facilities, distribution centers, high-traffic docks |

| PEX-9000 | Reliable performance for light industrial use | Lightweight dual-panel design, smooth swing operation, customizable finish | Medium | Light industrial spaces, prep rooms, general maintenance areas |

Each model offers a unique balance of strength, visibility, and long-term value. From high-traffic production floors to lighter-duty workspaces, there’s an option built to match your facility’s needs and keep your operations moving without interruption.

How to Choose the Right Industrial Impact Door for Your Facility

After knowing how Industrial Impact Doors stand apart from standard ones, the next step is finding the right fit for your facility. Every space has its own traffic demands and environmental conditions, here’s how to identify which door best meets your daily needs.

| Feature | Why It Matters |

|---|---|

| ✔Durability and Build Quality | Reinforced cores and heavy-duty hinges resist daily impacts from carts and equipment, preventing warping and keeping doors aligned for years of reliable use. |

| ✔Ease of Swing and Safety | Smooth two-way swing with return-to-center hinges supports steady traffic flow. Vision panels help staff see oncoming movement, reducing collision risks in busy zones. |

| ✔Customization and Fit | Multiple sizes, materials, and finishes let you match your layout and standards. Add-ons like kick plates, seals, and window options improve hygiene, insulation, and performance. |

| Application | Recommended Model & Why |

|---|---|

| ✔Warehouses | PE-9000 for extreme durability in equipment-heavy areas; handles high-cycle, high-impact use without slowing operations. |

| ✔Cold Storage | PE-1500 with full-perimeter seal to preserve temperature and sanitation in freezers, coolers, and prep zones. |

| ✔Production Lines | PE-8000 offers wide openings and smooth two-way access for carts, pallets, and machinery on fast-moving lines. |

| ✔Light Industrial Spaces | PEX-9000 balances cost and performance for moderate traffic in storage, maintenance, and prep areas. |

Choosing the right Industrial Impact Door ensures long-term reliability and smoother operations. Contact our experts today for personalized recommendations or a custom quote that fits your facility’s exact needs.

Frequently Asked Questions

FAQs – Industrial Double Doors

What are industrial double doors and where are they most useful?

Industrial double doors are designed for high-traffic areas where people, carts, or forklifts move constantly, such as warehouses, production floors, and loading docks. They keep spaces organized and efficient by allowing easy two-way access.

What’s the best industrial double door for busy warehouse traffic?

The PE-9000 industrial double door is built for warehouses and logistics centers. Its heavy-gauge panels and reinforced hinges handle nonstop movement while preventing downtime.

Can industrial double doors be customized to match my facility’s layout or finish?

Yes, all PE-Series models can be tailored for your space. You can customize size, finish, color, and add options like kick plates or vision panels for improved durability and safety.

Are industrial double doors insulated for temperature-controlled environments?

The PE-1500 industrial double door includes a full-perimeter seal that maintains temperature stability in cold rooms, clean zones, and food prep areas, perfect for industries that require climate control.

How often should I inspect or maintain industrial double doors?

Check your doors every few months for alignment, hinge wear, and seal condition. Regular cleaning keeps the panels performing smoothly, especially in heavy-use zones.

What’s the difference between PE-Series double doors?

PE-Series doors (like the PE-8000 and PE-9000) are built for rugged, high-traffic environments while PE-1500, focus on sanitation and temperature control for food-safe facilities.

Can these doors handle forklift or pallet jack traffic?

Yes. The PE-8000 and PE-9000 both feature wide panels and impact-resistant cores, making them ideal for forklifts and pallet jacks.

Do industrial double doors help reduce noise in busy facilities?

Yes. Many models, including the PEX-9000, use insulated cores that minimize noise transfer between departments, keeping workspaces quieter and more focused.

Can these doors improve energy efficiency?

Absolutely. Sealed-frame designs like the PE-1500 help prevent temperature loss, improving HVAC efficiency in cold or controlled environments.

Are industrial double doors easy to clean and sanitize?

Yes. All models feature smooth, non-porous surfaces that wipe clean easily. The PE-1500 is especially suited for washdown zones and hygienic environments.

Can I use industrial double doors in washdown or USDA-compliant areas?

Yes. The PE-1500 uses stainless components and sealed frames designed for frequent washdowns and compliance with USDA sanitation standards.

How do industrial double doors enhance safety?

Features like clear vision panels and soft-return hinges improve visibility and control. The PE-9000’s strong core also absorbs impact safely, reducing accident risk.

What are industrial double doors made of?

They’re constructed from high-impact ABS or thermoplastic panels with aluminum or stainless hardware. This blend ensures strength, long lifespan, and easy upkeep.

Can I install industrial double doors in existing openings?

Yes. Most models can be retrofitted into existing frames without major construction. Professional installation ensures proper sealing and balance.

Do industrial double doors help with dust and contamination control?

Yes. Sealed-frame models like the PE-1500 help prevent dust, debris, and cross-contamination, ideal for clean rooms, prep areas, and packaging spaces.

How long do PE-Series doors typically last?

With routine maintenance, industrial double doors can last many years. The PE-9000 and PE-1500 are built to withstand thousands of cycles in high-use environments.

Are there lightweight options for smaller or low-traffic areas?

Yes. The PEX-9000 provides excellent reliability in moderate-traffic spaces like storage rooms or maintenance areas without overbuilding for heavy use.

What industries use industrial double doors most often?

These doors are common in food processing, manufacturing, logistics, healthcare, and retail backrooms, anywhere safety, efficiency, and hygiene are priorities.

Are these doors available in different colors or finishes?

Yes. PE--Series doors are available in various finishes to match your facility design, from neutral industrial tones to custom color options.

How can I get a quote or schedule a consultation?

Simply reach out through our contact form or give us a call. We’ll help you select the right industrial double doors based on your facility type, traffic volume, and budget.

Photo Gallery

Find the Perfect Industrial Double Doors for Your Space

Industrial double doors keep your facility efficient, safe, and organized. From temperature control to heavy-duty performance, each model serves a unique purpose: PE-1500, PE-8000, PE-9000, and PEX-9000. Together, they improve workflow, protect work zones, and ensure lasting reliability. Ready to upgrade your space? Request a quote today and discover which industrial double doors fit your facility best.

Smart Door Solutions for Compact Workspaces