Warehouse Doors

In fast-moving warehouses, constant forklift traffic and daily impacts push standard doors to their limit. That’s why choosing the right door matters. Warehouse Impact Doors improve safety, efficiency, and durability in high-traffic environments. This guide covers what they are, top models, key comparisons, and how to choose the best fit for your facility.

Built to Meet Industrial Safety Standards

Warehouse Impact Doors are designed to handle nonstop traffic, protect openings from damage, and help your team move efficiently. From forklift lanes to temperature-controlled areas, our PE and PEX Series doors deliver unmatched strength and reliability. Choose the right model for your warehouse and experience better safety, smoother flow, and long-term performance. Contact us today to request a quote and get expert guidance for your facility.

What Are Warehouse Impact Doors and Why They Matter

In nonstop warehouse environments, every door affects how efficiently people and equipment move. Warehouse Impact Doors are built to handle that pressure, combining smooth traffic flow with lasting protection. They’re made for industrial spaces where equipment and staff pass through zones continuously throughout the day.

What Makes Warehouse Impact Doors Different

Built for Strength and Reliability

Warehouse Impact Doors stand apart from standard swinging doors because of their durable construction and high-performance design. They’re made with reinforced panels that resist dents and protect against constant equipment contact, ensuring long-term use in busy facilities where durability matters most.

Designed for Speed and Efficiency

These doors are equipped with sturdy hinges that support nonstop movement and tight perimeter seals that help regulate temperature. Each one swings open in both directions, allowing hands-free access that keeps workflow smooth, traffic steady, and operations running safely throughout the day.

Why Warehouse Impact Doors Matter

Improving Safety and Reducing Damage

Warehouse Impact Doors help create safer work environments by absorbing impact and protecting openings from heavy equipment. Their tough construction minimizes door damage and helps prevent costly repairs. Clear vision panels give staff better visibility, reducing the chance of collisions and keeping workflow safe and predictable.

Controlling Environments and Boosting Efficiency

These doors do more than protect, they help regulate airflow and maintain consistent temperatures between work zones. By minimizing energy loss and separating areas effectively, they improve comfort and efficiency across your facility. Each model is tailored for specific environments, from forklift lanes to temperature-controlled storage spaces.

The Best Warehouse Impact Doors for Your Facility

Every warehouse runs differently, so the right door depends on your workflow, traffic level, and equipment use. Each Warehouse Impact Door model is built for a specific application, matching the pace and movement patterns of your facility. Explore which one fits your warehouse best below.

The PE 8000 is designed for nonstop movement in high-traffic areas where forklifts and pallet jacks operate all day. It delivers unmatched protection and insulation to keep your workflow smooth and reliable.

• Insulated core helps maintain stable temperatures in high-activity areas.

• Full-perimeter seal minimizes air loss between zones.

• Reinforced bumpers protect against constant forklift contact.

• Smooth two-way swing keeps traffic moving efficiently.

PE 9000 – Engineered for Cold Storage and Extreme Use

The PE 9000 is built for facilities that demand maximum performance in temperature-controlled or heavy-use environments. It’s ideal for cold storage areas and production spaces where strength and insulation are equally important.

• Superior insulation keeps temperature-sensitive zones consistent.

• Reinforced panels resist heavy impacts and daily wear.

• Tight sealing edges prevent condensation and frost buildup.

• Easy two-way swing supports hands-free operation in cold environments.

The PE 1500 offers the perfect balance of strength and flexibility for moderate-traffic zones. It’s a dependable choice for staging areas, prep corridors, and supply rooms that need daily access without heavy machinery.

• Ideal balance of durability and flexibility for daily use.

• Two-way swing ensures efficient movement of carts and staff.

• Strong frame resists scratches and dents in narrow spaces.

• Simple design fits easily into existing warehouse openings.

The PEX 9000 is designed for areas where staff and carts move frequently but forklifts are not in use. Its lightweight build provides smooth movement, clear visibility, and a safer working environment.

• Fast-swing design improves pedestrian traffic flow.

• Clear vision panels maintain visibility between rooms.

• Lightweight build minimizes wear on hinges and frames.

• Ideal for packing lines, maintenance corridors, or neutral work zones.

Warehouse Impact Doors vs Traditional Doors

Once you’ve identified your warehouse’s needs, it’s easier to see how impact doors stack up against traditional options in daily performance and long-term value. The table below shows the key differences that impact safety, efficiency, and return on investment.

| Feature | Traditional Warehouse Doors | Warehouse Impact Doors |

|---|---|---|

| Traffic Handling | Manual operation limits movement and causes delays in busy zones. | Hands-free, two-way swing keeps forklifts and staff moving smoothly. |

| Durability | Panels dent and warp easily under constant impact. | Reinforced panels and bumpers resist heavy traffic and daily wear. |

| Energy Efficiency | Poor sealing leads to heat loss and uneven temperatures. | Tight perimeter seals maintain climate control and cut energy costs. |

| Safety & Visibility | Limited visibility increases collision risks. | Clear vision panels improve awareness and reduce workplace accidents. |

| Maintenance | Frequent repairs drive up long-term costs. | Strong materials require minimal maintenance and downtime. |

| ROI | Lower upfront cost but shorter lifespan and more repairs. | Delivers greater long-term value through energy savings and durability. |

Seeing the differences side by side makes it clear why impact doors are the better investment for busy facilities. They’re built for safety, efficiency, and long-term performance, helping warehouses stay productive while reducing overall operating costs.

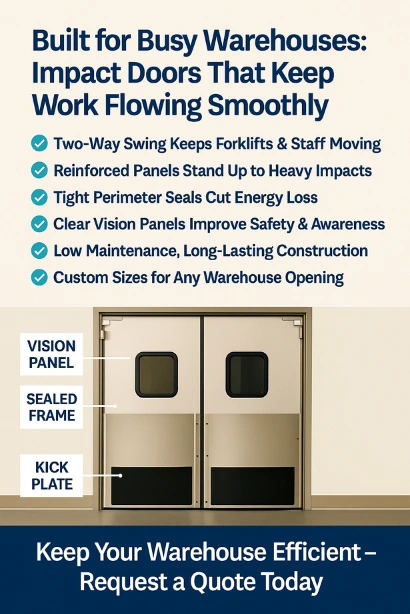

Key Features of Warehouse Impact Doors

Warehouse Impact Doors are designed to handle the unique demands of busy industrial facilities. From high-traffic corridors to climate-controlled zones, each feature has been engineered to improve workflow, protect equipment, and maintain a safer environment. Below are the top features that make these doors essential for modern warehouses.

| Feature | Why It Matters |

|---|---|

| ✅ Full-Perimeter Seals for Hygiene and Temperature Control | Helps maintain clean, climate-controlled environments by minimizing air exchange and keeping out contaminants, ideal for cold rooms and prep zones. |

| ✅ Tear-Drop Bumpers and Kick Plates | Protects the door surface from frequent impact by carts or boots, reducing long-term damage and extending service life. |

| ✅ Rust-Resistant Hardware for Washdown Zones | Built for sanitation routines, stainless components resist corrosion from frequent high-pressure cleaning and moisture exposure. |

| ✅ Clear Vision Panels to Reduce Collisions | Enhances safety in busy corridors by providing visibility through the door — especially helpful in high-traffic, fast-paced meat processing areas. |

| ✅ Durable Foam or ABS Cores That Hold Up Under Stress | These industrial-grade cores are engineered for durability under constant pressure — ideal for facilities where doors take repeated impact and still need to perform. |

These features combine to make Warehouse Impact Doors a reliable, efficient, and safe solution for every high-traffic or specialized warehouse environment. By choosing doors with these key components, your facility can improve operational efficiency, reduce damage, and maintain a consistent, controlled workflow across all zones.

Frequently Asked Questions

FAQs – Warehouse Impact Doors

Why should I choose a Warehouse Impact Door over a standard swinging door?

Warehouse Impact Doors, like the PE 8000 or PEX 9000, provide reinforced panels, two-way swing, and tighter perimeter seals. They are ideal for busy warehouses where safety and smooth traffic flow are priorities.

Can PE 8000 or PE 9000 doors handle daily forklift traffic?

Yes. The PE 8000 and PE 9000 are designed for constant forklift and pallet jack activity. Their reinforced construction keeps doors functional and safe under daily heavy use.

How do Warehouse Impact Doors help reduce energy costs?

Models such as the PE 9000 feature tight perimeter seals that maintain consistent warehouse temperatures. This reduces energy loss in climate-controlled zones, saving on heating and cooling bills.

How long do Warehouse Impact Doors typically last?

With proper installation, PE and PEX Series doors can last for many years. Durable panels and hardware ensure minimal wear even in high-traffic areas.

Can Warehouse Impact Doors be installed on existing frames?

Yes. Many models, including the PE 1500 and PEX 9000, fit existing openings with minimal modification. This makes upgrades fast and cost-effective.

Which door works best for cold storage zones?

The PE 9000 is ideal for cold storage or temperature-sensitive areas. Its insulated core and reinforced panels help maintain consistent climate control.

Which door is recommended for loading docks?

The PE 8000 is perfect for high-traffic loading zones. Its full-perimeter seal and bumpers protect the door while ensuring forklifts and staff move efficiently.

Are these doors safe for areas with only pedestrian traffic?

Yes. The PEX 9000 is lightweight yet strong, designed for staff and cart traffic. Clear vision panels increase visibility and prevent collisions.

How often do these doors require maintenance?

Minimal maintenance is needed. Reinforced materials and bumpers reduce wear, and stainless hardware resists corrosion, even in washdown or humid zones.

Can I request a custom size for my warehouse door?

Absolutely. All models, including PE 8000 and PEX 9000, can be customized to fit your facility’s width, height, and layout. Contact us to request a quote.

Do vision panels really help prevent collisions?

Yes. Clear vision panels on doors like the PE 1500 and PEX 9000 allow staff to see oncoming traffic, reducing accidents in fast-moving areas.

Are these doors suitable for humid or washdown zones?

Yes. Stainless hardware and industrial-grade cores resist corrosion and maintain functionality even under frequent cleaning.

Can Warehouse Impact Doors handle uneven warehouse floors?

Yes. Reinforced hinges and durable swing mechanisms accommodate slight floor irregularities while maintaining smooth operation.

How fast can these doors be installed?

Installation varies by size, but many doors, including PE 1500 models, can be installed in a single day, minimizing downtime in your warehouse.

Do PE-series doors have insulated cores?

Yes. PE 8000 and PE 9000 doors include insulated cores for energy efficiency, ideal for climate-sensitive or cold storage zones.

How do these doors improve workflow efficiency?

Two-way swing and hands-free operation keep staff and equipment moving without delays, improving overall warehouse productivity.

What safety features are included in Warehouse Impact Doors?

Key safety features include vision panels, reinforced bumpers, and smooth swing operation to prevent collisions and accidents.

Can these doors be used in mixed-traffic warehouses?

Yes. Different models serve various traffic levels, from forklifts to pedestrian zones, making them flexible for mixed-use facilities.

Can existing standard doors be upgraded to impact doors?

Yes. Many warehouses replace traditional swinging doors with PE or PEX models to gain better durability, energy efficiency, and safety.

How can I request a quote for a Warehouse Impact Door?

You can contact our team with your facility’s layout, traffic type, and preferred model. We provide a tailored quote and recommendations to ensure the perfect fit.

Photo Gallery

Keep Your Warehouse Safer and More Efficient

Warehouse operations run smoother with doors built for your facility’s pace. Warehouse Impact Doors ensure efficient movement, reduce collisions, and provide lasting protection. Ready to improve safety and efficiency? Contact us today to request a quote for the PE 8000, PE 9000, PE 1500, or PEX 9000 Warehouse Impact Doors.

Efficient Storage Room with Impact Doors