Manufacturing Room Swinging Doors

Traffic jams are common in manufacturing rooms when carts, pallet jacks, and staff crowd narrow doorways. This article explains how industrial swinging doors improve movement and safety on busy production floors. You will also learn which door models fit different traffic levels, how they compare, how to choose the right one, and answers to common questions.

Built for Industrial Performance

Industrial swinging doors help manufacturing rooms maintain a steady workflow by reducing congestion, improving visibility, and supporting smooth two-way movement across busy production areas. With durable construction designed for heavy use, these doors allow staff and equipment to move quickly and safely without slowing down operations. Whether you're managing high traffic, protecting equipment flow, or improving staff efficiency, upgrading to the right swinging door model can make a meaningful impact on daily performance.

How Industrial Swinging Doors Prevent Traffic Jams

Industrial swinging doors support the fast pace of manufacturing rooms by helping people and equipment move without unnecessary stops. Their design reduces slowdowns at doorways and brings more order to busy production areas, especially when traffic rises during peak activity.

Designed to Improve Daily Movement

Easy Two Way Access

Swinging doors help staff, carts, and pallet jacks move through busy areas without slowing down. Their smooth two way swing lets people pass in both directions quickly, reducing the stops that often cause traffic buildup in tight spaces.

Supports Steady Workflow

Because movement stays continuous, teams avoid crowding at doorways during shift changes or peak production times. This consistent flow keeps tasks on schedule and helps maintain a more organized pace throughout the day.

Built for Safety and Constant Use

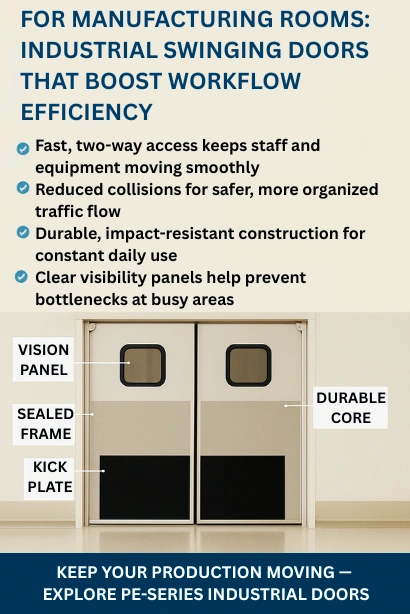

Better Visibility for Safer Movement

Vision panels give staff a clear view of who or what is approaching on the other side of the doorway. This reduces the chance of collisions in fast moving areas and helps everyone navigate the space with more confidence.

Durable Enough for Daily Demands

The impact resistant construction stands up to frequent use without bending or denting. By preventing damage that slows work, these doors support a safer environment and help keep production running on schedule.

Best Swinging Door Options for Manufacturing Rooms

Different production areas have different traffic demands, so choosing the right swinging door model helps support smoother movement throughout your facility. Below are four options designed to match the needs of various manufacturing environments.

The PE 8000 supports busy production floors that stay active throughout the day. Its strong build helps it perform consistently even when movement is steady.

• Works well for nonstop activity

• Helps maintain reliable daily flow

• Ideal for frequent staff and cart movement

PE 9000: Heavy Duty Strength for Rugged Zones

The PE 9000 suits industrial areas where heavy equipment is common. Its design helps it manage tougher conditions without slowing work.

• Handles frequent equipment use

• Supports heavier traffic demands

• Good fit for pallet jack and forklift areas

The PE 1500 is a practical choice for moderate traffic areas that still need dependable performance. It supports daily activity without requiring industrial grade strength.

• Affordable option for daily use

• Supports routine staff movement

• Great for cart heavy passageways

The PEX 9000 is designed for wider openings and areas with large equipment flow. Its structure helps support demanding conditions where space and durability matter.

• Works well for wide entry points

• Helps manage larger load movement

• Strong fit for intensive use environments

Choosing the Right Door Made Simple

With several swinging door models available, it helps to compare them side by side. The table below highlights the environments they work best in, the traffic levels they support, and the core strengths that make each model a practical choice for different manufacturing needs.

| Door Model | Best For | Traffic Level | Key Strengths |

|---|---|---|---|

| PE 8000 | Busy production floors | Very High | Heavy duty build ideal for nonstop movement |

| PE 9000 | Rugged industrial zones | High | Durable design that handles frequent forklift or pallet jack traffic |

| PE 1500 | Moderate manufacturing areas | Medium | Reliable and affordable, good for routine staff and cart movement |

| PEX 9000 | Large or intensive use environments | Very High | Supports wide openings and high equipment flow |

Seeing the models side by side makes it easier to match each option to your facility’s workflow. Whether your production floor handles heavy equipment, steady foot traffic, or larger load movement, this comparison helps narrow down the door that best fits your daily demands.

How to Choose the Right Swinging Door for Your Production Floor

Choosing the right swinging door starts with understanding how your facility moves. Each manufacturing space has different traffic patterns, equipment needs, and safety requirements, so taking a closer look at these factors helps you match your workflow to the most suitable model.

| Checklist Item | Why It Matters for Your Production Floor |

|---|---|

| ✅ Traffic Volume and Equipment Size | Helps you decide how strong and wide the door needs to be so it can support daily movement without slowing staff or equipment in your busiest areas. |

| ✅ Doorway Width and Visibility | Ensures the opening is sized correctly for carts or machines and that staff can see through the doorway where needed to move with more confidence. |

| ✅ Long Term Performance and Environment Control | Helps you choose a model that stands up to frequent use while also supporting needs like dust control, temperature separation, or lower noise in key rooms. |

When you match your traffic level, workspace layout, and long-term needs to the right door model, it becomes easier to support a smoother and safer workflow across your production floor.

Frequently Asked Questions

FAQs: Industrial Swinging Doors for Manufacturing Rooms

How do industrial swinging doors help reduce traffic jams on a production floor?

They keep movement continuous by letting staff, carts, and pallet jacks pass through without stopping. The two way swing cuts down on bottlenecks in narrow spaces and supports smoother daily flow.

What is the best industrial swinging door for heavy equipment like forklifts?

The PE 9000 industrial swinging door is the strongest fit. Its reinforced build handles frequent forklift and pallet jack movement, making it ideal for rugged, equipment heavy zones.

Are industrial swinging doors safe for high traffic manufacturing areas?

Yes. Doors with vision panels and smooth swing action help staff see activity on the other side, reducing collisions in busy areas.

Can industrial swinging doors be customized for wider or taller openings?

Yes. The PEX 9000 wide opening industrial swinging door is designed to accommodate large entryways and heavy equipment flow.

What is the difference between the PE 8000, PE 9000, PE 1500, and PEX 9000?

The PE 8000 is for nonstop activity, the PE 9000 is for rugged equipment zones, the PE 1500 fits moderate traffic, and the PEX 9000 supports wide openings and demanding use.

Do industrial swinging doors help with noise or temperature control?

Yes. Many models help limit noise transfer and improve separation between work zones, which keeps the environment more organized and efficient.

What maintenance do swinging doors require in busy facilities?

Most models need simple cleaning and occasional hardware checks. Their impact resistant design reduces long term upkeep.

How do I know which swinging door model is right for my production floor?

Match your traffic level and equipment size to the model. For example, the PE 1500 works well for routine staff movement, while the PE 8000 supports nonstop activity.

Can swinging doors help prevent collisions in fast moving areas?

Yes. Vision panels used in models like the PE 8000 and PE 9000 give staff a clear view of oncoming traffic, improving safety.

Are swinging doors strong enough for constant daily use?

Models such as the PE 8000 and PE 9000 are designed for heavy, repeated impact and can withstand continuous movement throughout the day.

Do swinging doors work well in narrow passageways?

Yes. Their smooth two way operation keeps movement steady in tight corridors without slowing down teams.

Can swinging doors improve workflow during shift changes?

Yes. Since workers can pass through quickly in both directions, these doors help prevent crowding during peak transitions.

Are industrial swinging doors a good fit for cart heavy areas?

The PE 1500 industrial swinging door is a strong choice for areas with steady cart traffic, offering reliable performance without overbuilt features.

Do these doors help with organizing movement in large facilities?

Yes. Pairing wide doorways with the PEX 9000 industrial swinging door helps guide equipment flow and prevents slowdowns.

Can I upgrade an existing doorway to fit a swinging door?

In most cases, yes. Many facilities replace older hinged doors with PE series swinging doors for better movement and visibility.

How durable are PE series swinging doors?

They use impact resistant materials that hold up under constant use. This helps prevent dents or damage that interrupt operations.

Do swinging doors help reduce downtime?

Yes. Because staff and equipment can move smoothly without stopping, production stays on schedule more easily.

Are swinging doors easy for staff to use?

Yes. The lightweight swing action makes it simple for workers pushing carts, carrying tools, or operating equipment to pass through without slowing down.

What benefits do vision panels provide on a production floor?

They increase awareness, reduce collisions, and create a safer flow of movement through busy sections of the facility.

Can swinging doors support high impact or demanding conditions?

Yes. The PEX 9000 and PE 9000 industrial swinging doors are engineered for tougher environments where larger loads and constant impact are expected.

Photo Gallery

Making the Right Choice for Your Production Floor

Choosing a door that fits your facility’s workflow helps create a more organized and reliable production environment. Each model offers strengths that support different activity levels, whether your space manages steady cart movement, rugged equipment zones, or wider pathways that handle larger loads. If you're planning improvements or exploring options for better movement throughout your facility, you can review the available swinging door models or request guidance to find the most suitable choice for your production needs.

Smooth Traffic Flow