Clean Room Swinging Doors

Clean rooms need door systems that control contamination and support smooth movement. Swinging doors help by reducing touchpoints, protecting airflow, and allowing staff and carts to move easily between zones. In this guide, you will learn how these doors improve clean-room performance, which PE-Series models are best to consider, how to choose the right option, and answers to common questions.

Engineered for Clean-Room Standards

Clean rooms rely on door systems that support both sanitation and daily workflow, and swinging doors offer a practical solution. With low-touch access, reliable closing, and materials that are easy to clean, they help maintain a safer and more controlled environment. Models like the PE-620ALC, PE-710, PE-720, and PE-8000 give facilities flexible options that match different levels of traffic, equipment movement, and hygiene requirements, making clean-room operations smoother and more efficient.

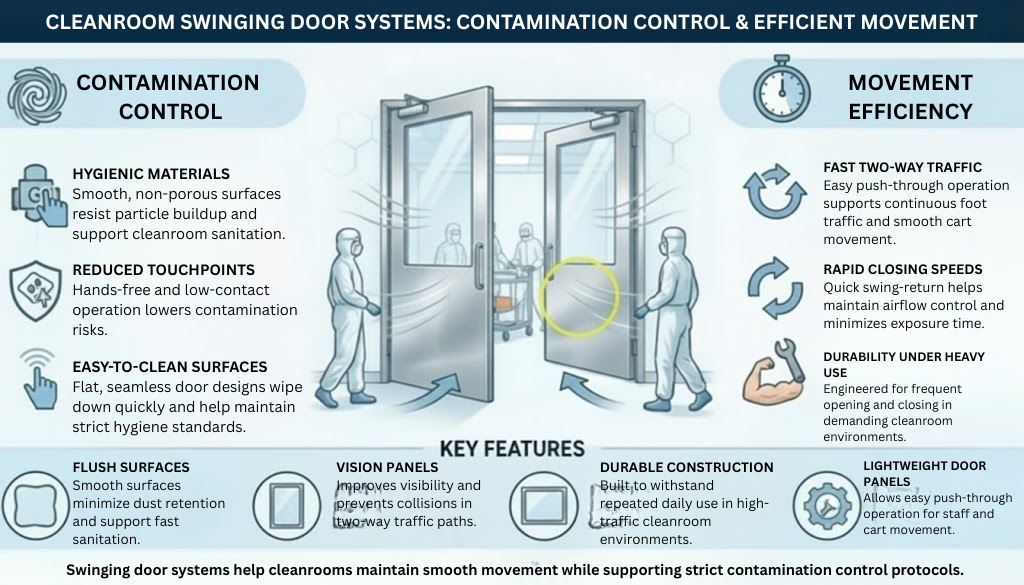

How Swinging Doors Keep Contamination Low and Movement Efficient

Clean rooms work best when every movement supports cleanliness and organization. Swinging doors help maintain these conditions by creating a controlled path between zones. The features below show how they contribute to better contamination control and smoother daily activity inside clean room environments.

Clean Movements That Help Protect the Environment

Reduced Contact for Cleaner Movement

Swinging doors help limit unwanted contact by allowing users to move through without grabbing handles. This low touch access supports cleaner daily activity and helps reduce chances of introducing particles into controlled areas.

Quick Closing That Supports Air Control

The fast closing action helps maintain stable air pressure between clean room zones. This steady airflow plays an important role in reducing particle spread and supporting teams that depend on consistent cleanliness throughout the day.

Smooth Access That Supports Safer Daily Activity

Bi Directional Access for Steady Workflow

Bi directional movement allows staff and carts to pass through without stopping. This helps maintain steady progress during busy hours and keeps clean room activity from slowing down when teams need to move between areas quickly.

Visibility Features That Improve Safety

Visibility panels help users see who or what is on the other side before entering. This added awareness reduces the chance of collisions and supports more organized movement, especially in clean rooms with frequent foot traffic and equipment use.

Best Swinging Door Models for Clean Rooms

The PE Series offers several door options that support different clean room layouts and activity levels. Each model provides features that help facilities maintain cleaner conditions while keeping movement steady. The options below can help you decide which door aligns best with your workflow needs.

The PE-620ALC supports clean rooms that need strong sanitation and clear visibility. Its reinforced surface works well in areas with frequent cleaning, and the window panel helps staff view activity before entering, which supports smoother and safer movement inside busy environments.

• Stainless steel surface support

• Clear visibility window

• Reliable daily performance

PE-710: Lightweight Operation for Steady Clean Room Foot Traffic

The PE-710 is a lightweight option designed for clean rooms with steady foot traffic. Its smooth finish makes regular cleaning simple, and the easy operation helps staff move comfortably throughout the day without slowing workflow. This model fits controlled spaces that rely on frequent entry and exit.

• Lightweight and easy to use

• Smooth and cleanable surface

• Suitable for steady movement

The PE-720 offers flexibility for clean rooms that handle carts or require wider access. Its ABS construction provides dependable strength without unnecessary weight, and the single or double panel option allows facilities to match the door setup to their space and daily workflow.

• ABS durable construction

• Single or double panel

• Fits wider pathways

The PE-8000 is designed for clean rooms that experience heavy activity or repeated equipment movement. Its industrial build supports demanding tasks, and the wider design works well in high traffic zones where reliability and long term performance are essential for daily operations.

• Industrial grade strength

• Ideal for high traffic

• Long term durability

Choosing the Right Door at a Glance

With several PE Series options available, it helps to see how each model compares side by side. The table below highlights what each door is best suited for and the strengths that make them useful in controlled environments. This quick view can guide you toward a model that supports your clean room activity levels and long term workflow needs.

| Door Model | Best For | Key Strength | Clean Room Advantage |

|---|---|---|---|

| PE-620ALC | Sanitation and visibility | Stainless steel protection with window | Cleanable surface and clear sightlines |

| PE-710 | Light to moderate traffic | Lightweight thermoplastic | Easy to sanitize and fast to operate |

| PE-720 | Busy aisles and equipment use | ABS construction with flexible panels | Wider access and smooth flow |

| PE-8000 | Heavy duty movement | Industrial durability | Handles demanding traffic reliably |

This comparison makes it easier to match each door model to the needs of your clean room. Once you know your traffic levels and the type of equipment used in your space, choosing a door that supports your workflow becomes much clearer.

How to Choose the Right Swinging Door System for Your Clean Room

Once you compare the PE Series models side by side, the next step is choosing a door that fits the needs of your clean room. Every facility follows different cleaning routines, traffic levels, and workflow patterns, so taking a closer look at these factors can help you select a door that supports reliable, long term performance.

| Factor | Why It Matters in Clean Rooms |

|---|---|

| ✔ Match the Door Material to Your Cleaning Routine | Different clean rooms follow different sanitation schedules. Choosing a door material that supports frequent cleaning helps maintain consistent results and reduces wear from regular disinfecting. |

| ✔ Consider Traffic Levels and Equipment Movement | Spaces with light foot traffic, steady daily movement, or frequent cart use each place different demands on the door. Matching the model to your traffic level keeps operation smooth throughout the day. |

| ✔ Choose a Size and Configuration That Fits Your Workflow | Single panels may work for smaller rooms, while wider double panels make it easier to move carts or larger supplies. Picking the right layout helps staff move efficiently between zones. |

| ✔ Evaluate Durability for Long Term Use | Active clean rooms need doors that can handle repeated use without losing performance. Looking at build quality and core strength helps you choose a model that stays dependable over time. |

By reviewing how your clean room operates and what it requires day to day, you can narrow down the PE Series model that best supports your workflow. These considerations make it easier to choose a door that stays reliable, cleanable, and efficient in your environment.

Frequently Asked Questions

FAQs About Swinging Doors in Clean Rooms

Are swinging doors safe to use in controlled clean-room environments?

Yes. PE-Series doors like the PE-620ALC and PE-710 offer cleanable surfaces and smooth operation that help protect airflow and limit unnecessary contact.

Do swinging doors help clean rooms maintain sterility standards?

They can. Models such as the PE-620ALC use cleanable surfaces and tight-fitting designs that help support sterility goals when paired with proper cleaning routines.

Which swinging door materials are easiest to clean in a clean room?

Clean rooms often prefer stainless steel or smooth thermoplastic surfaces. The PE-620ALC and PE-710 offer finishes that make daily sanitation simple.

Can swinging doors handle carts and equipment in busy clean-room corridors?

Yes. The PE-720 and PE-8000 support cart movement with durable cores and flexible panel options built for steady, repetitive traffic.

Are swinging doors customizable to fit different clean-room layouts?

Most PE-Series models, including the PE-720, allow customization for width, height, and vision panel placement to match your layout.

Do vision panels improve safety inside a clean room?

Yes. Models like the PE-620ALC include vision panels that help staff see oncoming traffic and avoid collisions.

Which PE-Series door is best for clean rooms with frequent foot traffic?

The PE-710 offers lightweight movement and smooth operation, making it a strong option for steady daily foot traffic.

What door works best for high-traffic clean rooms with equipment movement?

The PE-8000 provides industrial-grade durability for demanding environments with heavier or repeated equipment use.

Can swinging doors help reduce unnecessary touchpoints in clean rooms?

Yes. All PE-Series models offer hands-free, bi-directional access that limits hand contact and supports cleaner conditions.

Do swinging doors help maintain consistent airflow between clean-room zones?

They can. Quick-return hinges allow the doors to close promptly, supporting stable airflow patterns in controlled settings.

Are there options for wider door openings in clean rooms?

Yes. The PE-720 offers single and double-panel configurations for wider access points used for carts and equipment.

Are PE-Series swinging doors suitable for washdown or frequent cleaning cycles?

Models like the PE-620ALC with stainless steel surface support are built for frequent cleaning and moisture resistance.

How durable are swinging doors in clean-room conditions?

The PE-8000 provides the highest durability for demanding tasks, while the PE-720 and PE-710 offer reliable strength for moderate use.

Are these doors quiet enough for controlled clean-room settings?

Yes. PE-Series doors operate quietly, supporting calm environments where noise control matters.

Can swinging doors improve workflow in tight clean-room hallways?

They can. Models like the PE-710 and PE-720 enable bi-directional access that helps prevent backups and keeps movement steady.

Do swinging doors help prevent collisions in narrow clean-room aisles?

Yes. Vision panels on models such as the PE-620ALC improve visibility and reduce collision risks in busy aisles.

Are PE-Series doors compatible with different clean-room classifications?

They are suitable for many controlled environments. The PE-620ALC is often chosen for cleaner spaces with stricter sanitation needs.

Can clean rooms request special sizing or modifications for these doors?

Yes. Most PE-Series models can be ordered in custom sizes, including adjustments to width, height, and hinge placement.

Which swinging door is best for maintaining visibility between clean-room zones?

The PE-620ALC includes a clear window that supports safer, more coordinated movement.

How do I know which swinging door is right for my clean room?

Match the model to your daily workflow. The PE-710 fits steady foot traffic, the PE-720 suits wider access needs, and the PE-8000 supports demanding environments.

Photo Gallery

Cleaner, Safer, and More Efficient Clean Room Operations

Selecting a door system that supports the needs of your clean room helps create a more controlled and dependable work environment. The PE-Series models give facilities options that match different activity levels and layout requirements, making it easier to find a door that supports long term goals. By choosing a model that aligns with your workflow, you can help your team stay focused, maintain cleaner conditions, and keep movement inside your clean room steady and organized.

Efficient Clean Room Layout