Packaging Area Swinging Doors

Packaging areas rely on steady movement, clear pathways, and quick transitions between tasks. Swinging doors help maintain that flow by separating work zones without slowing teams down. With the right door setup, packaging areas become easier to navigate, safer for staff, and more efficient for daily operations.

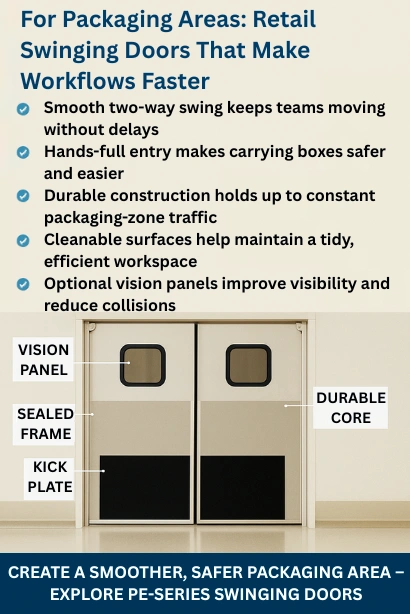

Engineered for Smooth Packaging-Area Flow

Retail swinging doors are a simple upgrade that makes packaging areas faster, safer, and easier to manage. Their two-way swing, durable build, and cleanable surfaces help teams move efficiently while protecting the workspace from clutter and congestion. With optional vision panels and reinforced cores, PE-series doors support both light and heavy-duty environments. If you want smoother workflow, fewer bottlenecks, and a more organized operation, the right swinging door can make a major difference.

How Swinging Doors Improve Movement and Efficiency in Packaging Areas

Packaging teams work best when movement feels natural and uninterrupted. After upgrading to swinging doors, the workspace becomes easier to navigate, especially during busy periods. These doors support a steady rhythm of activity that helps teams stay focused and productive throughout the day.

Smoother Movement and Hands Full Convenience

Better Flow Through Continuous Two Way Movement

Swinging doors support nonstop movement by letting staff pass from either direction without needing to stop and open a traditional door. This helps reduce slowdowns during busy hours and keeps workers moving at a steady pace. With consistent flow, daily tasks stay on track and the entire packaging process becomes easier to manage.

Easier Transitions When Carrying Boxes or Carts

Workers often move through packaging areas with their hands full, and swinging doors make those moments safer and more convenient. A light push is enough to enter or exit, even when guiding a cart or carrying bulky items. This simple convenience helps maintain steady pacing and allows teams to complete tasks with fewer interruptions

How Swinging Doors Keep Packaging Areas Moving Smoothly

Smoother Movement Through Busy Work Zones

Busy packaging rooms often involve multiple workers crossing paths, which can slow down progress. Swinging doors help organize these movements by giving teams a clear route in and out without hesitation. With less crowding at entry points, daily operations stay more predictable and comfortable for everyone.

More Efficiency During High Volume Tasks

During high demand periods, teams need tools that support quick decisions and steady output. Swinging doors help by keeping traffic flowing even when tasks pile up or materials arrive all at once. This dependable movement allows employees to stay on pace, complete jobs sooner, and handle increased workload with less stress.

Best Swinging Doors for Packaging Areas

Finding the right swinging door starts with understanding how each model supports movement, safety, and daily tasks inside a packaging area. The options below offer dependable performance across different traffic levels and workspace needs, helping teams stay productive and keep materials moving without slowdowns.

The PE-620ALC works well in compact or medium-traffic packaging rooms that need a dependable, cost-efficient swinging door. Its balanced design helps teams move smoothly through smaller spaces without slowing down.

• Ideal for light to medium daily movement

• Cleanable surfaces for easy upkeep

• Great value for budget-conscious facilities

PE-710: Designed for Fast, High-Traffic Movement

The PE-710 is built for packaging areas with constant in-and-out activity throughout the day. It supports steady foot traffic and helps teams move quickly while carrying parcels or guiding carts.

• Stronger build for frequent daily swings

• Smooth passage even during peak hours

• Helps reduce minor workflow delays

The PE-720 offers a versatile solution for packaging zones with mixed tasks and changing workloads. It provides durability, visibility, and reliable performance for teams that need flexibility.

• Clear vision panels for safer movement

• Balanced construction for everyday use

• Works well across different packaging tasks

The PE-8000 is designed for heavy-duty industrial packaging areas handling nonstop movement and heavier materials. Its reinforced build manages high-volume demands without wearing down quickly.

• Extra-durable construction for harsh conditions

• Reliable performance during long shifts

• Ideal for high-volume, industrial workflows

Choosing the Right Door for Your Packaging Area

Selecting the right swinging door starts with understanding how each model performs in different packaging environments. This comparison table offers a quick way to see which option matches your traffic level, daily tasks, and workflow needs.

| Door Model | Best For | Key Strengths |

|---|---|---|

| PE-620ALC | Light to medium-traffic packaging rooms | Cost-efficient, dependable, easy to maintain |

| PE-710 | Frequent foot traffic and cart movement | Durable build, smooth swing, ideal for repeat use |

| PE-720 | General packaging setups with mixed tasks | Balanced performance, good visibility, versatile choice |

| PE-8000 | Heavy-duty industrial packaging areas | Extreme durability, long lifespan, handles high-volume movement |

This table makes it easier to match each door model to your workflow demands. Whether your team handles light daily tasks or nonstop industrial movement, choosing the right door helps create a smoother, safer, and more efficient packaging area.

Practical Tips for Choosing the Right Door for Your Packaging Area

Selecting the right swinging door depends on how your packaging area functions day to day. By looking at traffic patterns, task types, and safety needs, you can choose a door that supports steady workflow and keeps your team moving without unnecessary slowdowns.

| Practical Tip | Why It Matters in Packaging Areas |

|---|---|

| ✓ Evaluate daily traffic level | Knowing whether your packaging area handles light, moderate, or heavy movement helps you choose a door that will not wear out early or feel oversized for the space. |

| ✓ Identify typical tasks | Looking at how often staff carry boxes, push carts, or handle rush orders makes it easier to select a door that keeps those tasks moving without slowdowns. |

| ✓ Plan for safety and zoning | Using doors to separate packing, storage, and shipping lanes improves safety, keeps paths clear, and helps teams understand where each task should happen. |

| ✓ Match door strength to workload | Aligning door strength and materials with how hard the area works ensures your swinging door can handle daily impact and still perform reliably over time. |

| ✓ Decide on visibility windows | Adding vision panels helps staff see who is on the other side of the door, which reduces collisions and keeps movement smoother in busy packaging lanes. |

These simple considerations make it easier to choose a door that fits your packaging area’s volume, layout, and safety needs. With the right features in place, your workflow becomes smoother, more predictable, and easier for your team to manage each day.

Frequently Asked Questions

Frequently Asked Questions About Swinging Doors in Packaging Areas

Are swinging doors safe for workers who carry heavy boxes or use carts?

Yes. PE-Series swinging doors open with a light push, which helps staff move safely even when their hands are full. Vision panels on models like the PE-720 also improve awareness in busier areas.

Which swinging door lasts longest in high-traffic packaging zones?

The PE-8000 is the most durable option for nonstop movement. Its reinforced build handles heavy use and daily impacts without wearing down quickly.

Do swinging doors help reduce congestion in tight packaging spaces?

They do. Two-way movement keeps staff flowing smoothly through narrow passages, and this helps reduce crowding during peak hours.

What is the best swinging door for a small packaging room?

The PE-620ALC works well for compact spaces. It offers dependable performance without taking up extra clearance, making it great for smaller work zones.

Can swinging doors be installed in existing packaging areas without major renovation?

Yes. PE-Series swinging doors are designed for simple installation, often using existing frames. Most setups require minimal adjustments.

How do swinging doors help improve daily workflow in packaging areas?

They reduce pauses caused by manual door operation, helping teams move quickly between tasks. This steady flow keeps operations running smoothly.

Do packaging areas benefit from vision panels on swinging doors?

Yes. Clear vision panels, available on the PE-710, PE-720, and PE-8000, improve visibility and help prevent collisions in fast-moving environments.

Are swinging doors easy to clean for packaging zones that require hygiene?

Absolutely. PE-Series doors use smooth, wipe-friendly surfaces that support routine cleaning and basic sanitation needs.

Which swinging door is best for packaging areas with mixed tasks and traffic levels?

The PE-720 is a versatile match. It handles shifting workloads, supports visibility, and performs well across different packaging activities.

How do swinging doors help keep packaging areas organized?

They act as simple transitions between stations, helping define zones without slowing movement or blocking access.

Will swinging doors hold up if carts or equipment bump into them?

Yes. Models like the PE-710 and PE-8000 include durable cores designed to absorb frequent contact and maintain performance.

What swinging door is recommended for large warehouses with heavy materials?

The PE-8000 is ideal. It is engineered for demanding, industrial-level work and manages high-volume movement with ease.

Are swinging doors quiet enough for packaging teams working in close quarters?

Yes. PE-Series doors use smooth hinges and balanced construction to reduce noise during frequent operation.

Do swinging doors help reduce the stop and start feeling in busy packaging lines?

They do. The ability to move through without stopping helps maintain a consistent workflow during high-volume shifts.

Can swinging doors improve safety in areas where workers cross paths often?

Yes. Two-way movement and vision panels reduce blind spots and make it easier for workers to move confidently through shared zones.

What is the most budget-friendly swinging door for packaging areas?

The PE-620ALC offers reliable performance at a cost-efficient price, making it a smart choice for smaller operations or light-traffic rooms.

Do swinging doors help teams complete tasks faster?

Yes. By eliminating the need to manually open or close doors, staff save time during every transition, which adds up throughout the day.

How do I know which swinging door model is right for my packaging area?

Evaluate your traffic level, daily tasks, and durability needs. The PE-620ALC suits lighter work, the PE-710 and PE-720 cover most daily operations, and the PE-8000 fits heavy-duty industrial zones.

Are swinging doors compatible with carts and material-handling equipment?

Yes. Their hands-free design works well with rolling carts and helps teams move materials more easily.

Do swinging doors help reduce workplace strain for packaging staff?

They do. Workers do not need to twist or lift to open a door, and this makes repetitive tasks easier, especially during long shifts.

Photo Gallery

Creating a Faster, More Efficient Packaging Area

Upgrading a packaging area becomes far easier when the door setup supports the way your team works. Swinging doors help maintain a steady pace throughout the day by giving staff a clear and reliable way to move between tasks. When you choose a model that matches your traffic level and daily workload, the entire space becomes more comfortable to navigate and easier to keep on schedule. With the right swinging door in place, your packaging area is better prepared for busy hours, shifting demands, and long-term growth.

Efficient Packaging Workspace