Factory Swinging Doors

Outdated factory doors can slow workers down and disrupt daily operations. Many facilities now look for replacement options that better support fast paced industrial work. This guide explains why swinging doors are becoming a preferred choice, highlights recommended models, provides a helpful comparison table, answers common questions, and offers simple guidance for choosing the right replacement for your facility.

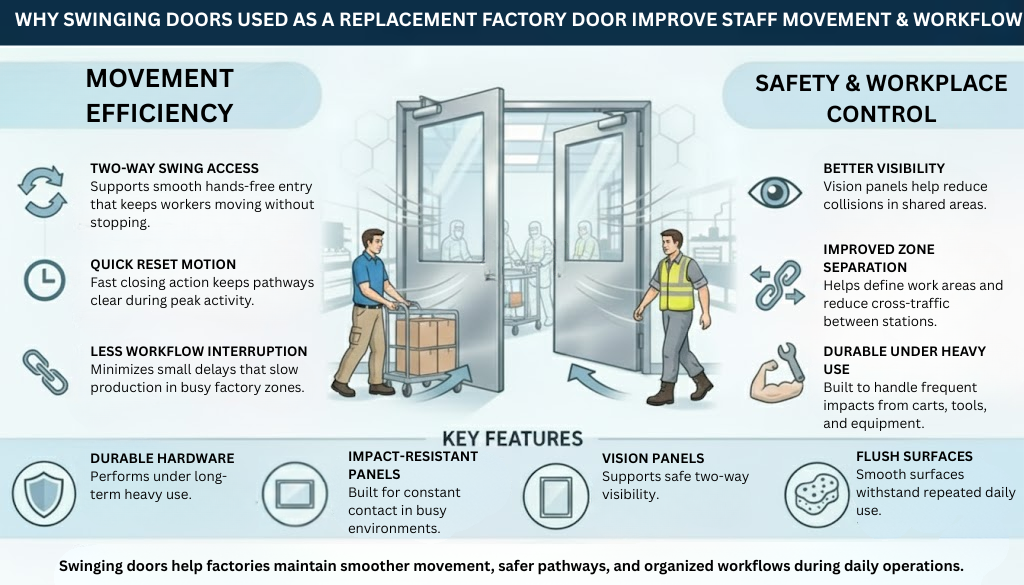

Built to Improve Staff Movement and Workflow

Swinging doors used as a replacement factory door help factories keep movement fast, safe, and consistent. Their two-way swing, hands-free operation, and self-closing motion allow workers to move smoothly through busy areas without slowing down. When paired with durable models like the PE-1500, PE-8000, PE-9000, and PEX-9000, facilities get long-lasting performance designed for heavy traffic and demanding daily use. This upgrade creates a smoother workflow and a safer, more efficient workplace.

How Swinging Doors Improve Staff Movement in High Traffic Industrial Areas

Swinging doors support the fast paced movement that busy industrial areas depend on. Their design helps workers move confidently through shared spaces while keeping daily activity running smoothly. By reducing small interruptions and keeping pathways clear, these doors make it easier for teams to stay productive during constant foot traffic or equipment use.

Quick Entry That Keeps Staff Moving Efficiently

Easy Swing Action for Faster Entry

Swinging doors open with a light push so workers can move through without stopping or shifting what they are carrying. This simple motion supports a steady pace on busy floors and helps staff maintain focus on the task at hand. The ease of entry is especially useful when tools or materials need to be transported quickly.

Self Closing Motion That Keeps Pathways Clear

The two way swing helps movement continue in both directions during peak activity. After someone passes through, the door closes on its own to keep shared areas open for the next person. This predictable motion prevents crowding, reduces hesitation, and supports a smoother flow through narrow or high traffic pathways in the facility.

Consistent Operation That Reduces Daily Slowdowns

Smooth Movement That Supports Safer Daily Flow

The steady swing of these doors helps create a safer rhythm in high traffic areas where workers pass through often. Their predictable motion lowers the chance of bumps or collisions in narrow or shared pathways. This smooth operation helps teams move with more confidence during busy periods in the facility.

Reliable Reset Action That Keeps Work Areas Organized

Each time the door resets itself, pathways stay open and workstations remain clear for the next person. This consistent return motion prevents small delays that can build up throughout the day. It also supports a more organized flow in spaces where foot traffic, carts, or equipment move through the same routes again and again.

Recommended Swinging Door Models for Factory Door Replacement

After knowing how swinging doors improve movement, the next step is choosing the model that fits your facility’s needs. Each option below offers its own strengths based on traffic levels, equipment use, and the type of work happening in your space.

The PE 1500 is a practical choice for everyday factory use. It handles steady foot traffic and provides consistent swing action without frequent maintenance. This model works well in areas that need a simple and dependable door that stays reliable throughout the day, even when staff move through shared spaces regularly.

• Supports moderate to heavy foot traffic

• Low maintenance design for daily use

• Smooth swing action for steady movement

• Durable enough for regular activity

PE 8000 for Heavy Duty Industrial Zones

The PE 8000 is suited for facilities that face harsher conditions or nonstop activity. Its impact resistant build performs well during long shifts, especially in areas where equipment or materials are moved often. This model is a strong fit for teams that need a door capable of handling rugged workloads and frequent use.

• Works well in heavy duty or nonstop environments

• Impact resistant structure for tougher conditions

• Designed for continuous operation

• Ideal for areas with frequent equipment movement

The PE 9000 features a wider panel that supports the movement of larger items and carts. This added clearance helps prevent tight spots in areas where several workers or equipment pass through at once. It is a useful option for improving comfort and flow in pathways that require more room during busy periods.

• Wide panel design for equipment and carts

• Helps reduce congestion in narrow areas

• Supports high volume movement

• Ideal for busy lanes with frequent item transport

The PEX 9000 delivers the highest level of durability among the models listed. Its reinforced build performs consistently during demanding multi shift operations. This model is a dependable option for facilities that need long term reliability and a door capable of handling heavy traffic throughout the day.

• Reinforced for long term durability

• Suitable for multi shift industrial use

• Handles heavy and repeated traffic

• Designed for facilities needing maximum strength

Choosing the Right Swinging Door for Your Facility

Knowing each model side by side can make it easier to choose the door that best matches your daily traffic levels, equipment use, and workspace layout. Use the chart below to compare key features and typical applications so you can confidently select the option that fits your facility’s needs.

| Door Model | Best For | Traffic Level | Key Advantages | Typical Applications |

|---|---|---|---|---|

| PE 1500 | General factory use | Medium to heavy | Smooth swing, durable, low maintenance | Assembly areas, packing zones |

| PE 8000 | Harsh environments | Heavy, nonstop | Impact resistant, long lasting | Manufacturing floors, loading aisles |

| PE 9000 | Wide access needs | Heavy with carts | Wide panels, reduces bottlenecks | Equipment paths, transport lanes |

| PEX 9000 | Extreme durability | Extremely high | Strongest build, ideal for demanding use | High intensity production lines |

This quick comparison gives you a clearer look at how each model performs in different industrial environments. Whether your facility needs everyday reliability, extra clearance, or maximum durability, these options make it easier to match the right swinging door to your workflow and traffic demands.

Additional Benefits Beyond Movement

Even after choosing the right swinging door model, many facilities appreciate the extra advantages these doors bring to everyday operations. Beyond improving movement, they also support safety, durability, and better workspace organization in areas where equipment, tools, and staff constantly move through shared pathways.

| Benefit | Why It Matters in Industrial Facilities |

|---|---|

| ✓ Stronger protection for workers and equipment | Helps create a safer environment for staff moving tools, carts, or materials by reducing unexpected contact with equipment and supporting more controlled passage through shared pathways. |

| ✓ Better zone separation and cleaner workflow patterns | Defines work zones more clearly so noisy, busy, or sensitive areas stay separated, which supports cleaner operations and helps reduce cross traffic in focused work areas. |

| ✓ Durable construction that lowers maintenance costs | Industrial grade materials stand up to daily workloads, which cuts down on repairs and replacements over time and helps keep long term maintenance costs under control. |

| ✓ Resilient surfaces for rough or high impact use | Door surfaces are built to handle frequent bumps from carts, tools, or equipment without showing heavy wear, helping the doors stay presentable even in demanding areas. |

| ✓ Support for cleanliness and environmental control | Certain models help limit dust spread and air exchange between zones, which is useful for prep spaces, packaging lines, or storage areas where cleanliness and conditions matter. |

These added benefits give facilities more than just smoother movement. They help create a safer, cleaner, and more organized work environment while extending the life of the doors themselves. This makes swinging doors a strong long-term upgrade for industrial spaces that rely on consistent performance every day.

Frequently Asked Questions

FAQs About Swinging Doors Used as Replacement Factory Doors

Are swinging doors safe to use in busy factory areas?

Yes. Industrial swinging doors are designed for fast paced spaces where people and equipment move all day. Their predictable swing and sturdy build help reduce bumps and keep shared areas safer during regular activity.

Can swinging doors handle carts, equipment, or frequent impacts?

Most industrial models are built for repeated contact from carts and tools. Heavy duty options like the PE 8000 or PEX 9000 offer stronger surface protection for facilities that deal with nonstop equipment movement.

What swinging door model works best for factories that run nonstop?

Facilities that operate round the clock often choose the PEX 9000 because it is built for long term durability and repeated daily cycles. It performs well in spaces with intense, multi shift activity.

Do swinging doors help reduce bottlenecks and slowdowns?

Yes. Their two way swing and quick reset help workers move through tight areas without waiting. A wider model such as the PE 9000 also reduces congestion when equipment or carts need extra space.

How durable are industrial swinging doors compared to standard factory doors?

Industrial swinging doors are engineered to handle more impact, more traffic, and more daily wear than standard doors. Models like the PE 1500 or PE 8000 are designed to hold up in demanding work areas.

Are swinging doors easy to clean in industrial environments?

Yes. Many models use smooth, non porous surfaces that are simple to wipe down. This helps support cleanliness in prep areas, packaging zones, and production rooms that follow regular sanitation routines.

Do swinging doors help control noise between work zones?

In many cases, yes. Their solid panels create a natural barrier that helps limit noise from busy workstations, especially in areas where equipment or tools run throughout the day.

Can swinging doors help with temperature control in certain rooms?

Some models help reduce temperature loss by closing quickly and limiting air exchange. This is useful for storage areas, prep zones, and spaces that rely on consistent temperature levels.

Are vision panels recommended for improving safety?

Yes. Vision panels help workers see what is on the other side before entering, which can reduce collisions in tight or high traffic areas. This is especially helpful when carts or equipment move through shared pathways.

Which door works best for equipment corridors or wide transport paths?

A wider model like the PE 9000 is designed for equipment movement and helps prevent bottlenecks in areas that need extra clearance during busy hours.

Do swinging doors help separate clean zones from general work areas?

Yes. They create a clear boundary that helps limit dust movement and foot traffic crossover, which is helpful in packaging rooms, inspection zones, or areas with cleanliness standards.

Are swinging doors a good choice for facilities with frequent impacts?

Heavy duty models such as the PE 8000 and PEX 9000 are engineered to handle repeated contact from carts, tools, or transport equipment, making them a strong choice for rough use.

How long do swinging doors typically last in industrial environments?

Their lifespan depends on traffic levels, but models like the PE 1500 and PE 9000 are designed for consistent daily use. Many facilities choose them for their reliability over long periods of time.

Can swinging doors help keep workstations more organized?

Yes. Their quick self closing motion helps keep pathways clear so stations stay open for the next person. This supports cleaner, more organized workflow patterns in shared spaces.

Do swinging doors require a lot of maintenance?

Not usually. Many industrial models have simple components that do not need frequent adjustments. The PE 1500 is a popular low maintenance choice for general factory use.

Are swinging doors suitable for areas with moisture or cleaning routines?

Many doors use durable materials that handle moisture and regular cleaning. For tougher environments, the PE 8000 offers added resilience for washdown friendly zones.

Can swinging doors support facilities with constant foot traffic?

Yes. Industrial double doors are built for continuous movement. Models like the PE 9000 or PEX 9000 perform well in spaces where workers pass through all day.

Do these doors create any issues for workers carrying tools or materials?

No. Their light push entry and two way swing make it easier for workers to move through without putting items down or stopping, which helps maintain a steady work rhythm.

Are swinging doors a good replacement option for older factory doors?

Yes. They offer faster entry, more durability, and smoother operation than many older door styles. This makes them a practical upgrade for improving daily workflow in busy facilities.

How do I choose the right swinging door model for my facility?

It depends on traffic levels, equipment use, and how rugged the environment is. The PE 1500 suits everyday use, the PE 8000 fits harsher conditions, the PE 9000 works well for wider pathways, and the PEX 9000 is ideal for nonstop heavy activity.

Photo Gallery

Why Swinging Doors Are a Smart Replacement Factory Door

Swinging doors give factories a simple way to upgrade efficiency, safety, and daily workflow without adding complexity to the space. With durable models like the PE 1500, PE 8000, PE 9000, and PEX 9000, facilities can choose the exact strength and clearance they need for their traffic levels. If you're looking for a reliable replacement door that supports smoother operations, exploring these models is a practical next step.

Factory Prep Space